Enhancing the Single-Pane Glass Process with Precise Thermal Imaging

Boosting Efficiency and Product Quality with Under-Line Thermal Measurement

Challenge

Achieving uniform heating during glass tempering is difficult, especially for Low-E glass with reflective coatings. Conventional methods fail to measure actual surface temperatures, leading to quality issues, material waste, and production inefficiencies due to undetected stress points.

Solution

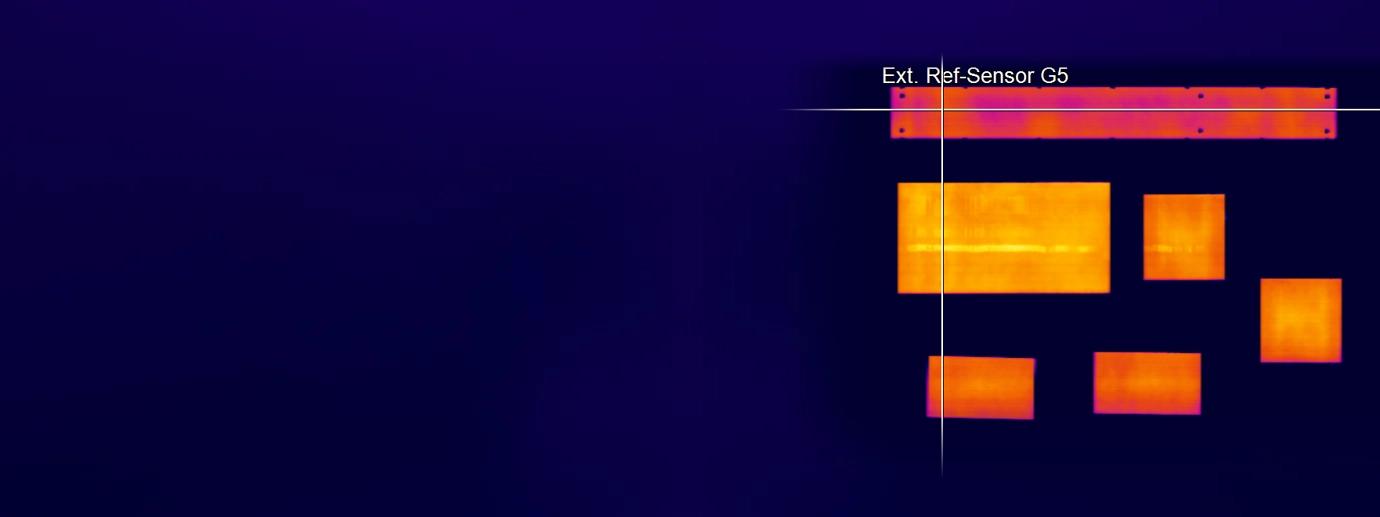

Installing bottom-up infrared thermal imaging systems enables real-time monitoring of actual glass surface temperatures. Measuring from the uncoated side of Low-E glass ensures accurate thermal profiling, leading to more consistent tempering and fewer production defects.

Benefits

- Ensures homogeneous heating and cooling for high-quality tempered glass

- Reduces material waste by preventing thermal stress-related defects

- Enables fast detection of fractures and immediate protective response

- Minimizes downtime with maintenance-free, integrated system setup

- Improves process efficiency with precise, real-time thermal control

Key Challenges in Temperature Control During Glass Tempering

The production of single pane safety glass (SPG) is a complex process that requires precise temperature control to ensure product safety and quality. SPG is created by heating flat glass in a tempering furnace and then rapidly cooling it. This tempering process strengthens the glass and ensures it shatters into small, blunt pieces when broken, significantly reducing the risk of injury. SPG is commonly used in applications where glass safety is critical, such as in building facades, vehicle windows, and shower doors.

Maintaining uniform temperature distribution across the glass surface is a critical challenge in tempering. If the glass is not heated evenly, it can develop stress points that may cause it to break during production or result in a substandard product. Traditional temperature measurement methods, such as thermocouples inside the furnace, only provide data on the oven temperature, not the actual glass surface temperature. This limitation can lead to inefficiencies and quality issues, especially when dealing with advanced materials like Low-E glass, which has a reflective coating that complicates temperature measurement.

Accurate temperature control ensures the glass meets safety standards and avoids production failures. Inconsistent temperature distribution can result in significant material waste and production downtime. As glass manufacturing processes become more advanced, precise temperature measurement systems are becoming increasingly important. Infrared temperature measurement, particularly with thermal imaging systems, offers a superior solution for directly monitoring the glass surface temperature and ensuring a homogeneous heating profile throughout the process.

Optimized Installation for Improved Temperature Measurement

To address the challenges of precise temperature control in single-pane safety glass production, two Bottom Up Glass Inspection System (BUGIS) variants, featuring the PI 450i G7 or the PI 640i G7 infrared cameras, offer a powerful solution. These systems are designed for process control in glass tempering machines and provide accurate, real-time temperature measurements. The PI 450i G7 or the PI 640i G7 are positioned beneath the glass, allowing them to capture precise thermal images from the uncoated side of Low-E glass, bypassing issues related to low-emissivity coatings.

The BUGIS 450i G7 system includes two PI 450i G7 imagers with an optical resolution of 382 x 288 pixels, ensuring comprehensive coverage of the glass surface. The cameras offer a wide field of view (FOV) of up to 80 x 54, allowing them to scan up to 3.4 meters at a distance of 90 cm. These infrared cameras operate at a frame rate of 80 Hz, which is essential for capturing the fast temperature changes during the tempering process. The system can measure temperatures between 150 °C and 1500 °C (302 °F and 2732 °F), ensuring flexibility for different types of glass.

For applications requiring even higher resolution, the BUGIS 640i G7 system employs the PI 640i G7 cameras, which offer an impressive 640 x 480-pixel resolution and a maximum field of view of 90 x 66. This enables the system to scan up to 4.3 meters at a 90 cm distance, providing larger coverage and detail. The PI 640i G7 operates at a frame rate of up to 125 Hz, allowing for high-speed temperature monitoring in dynamic environments. This makes it ideal for large-scale production lines where precise temperature control is critical.

Both systems come equipped with CTlaser 4ML glass breakage sensors, which accurately detect glass fractures. The integrated Digitally Controlled Lens Protection (DCLP) system protects the cameras from falling debris during production. Additionally, no cooling or air purging is required, simplifying installation and maintenance. The systems are delivered pre-assembled for quick and easy integration into existing tempering furnaces, and their data is managed through the PIX Connect software, which provides comprehensive analysis and control features.

The Bottom-Up Advantage for Low-E Glass

The implementation of the Bottom-up Glass Inspection Systems (BUGIS), combined with the high-performance infrared cameras PI 450i G7 or PI 640i G7, has significantly improved the single-pane safety glass production process. By providing highly accurate, real-time temperature data from the uncoated side of Low-E glass, these systems ensure consistent heating and cooling, leading to better product quality and reduced material waste.

One of these systems’ most significant advantages is their ability to detect even the smallest temperature deviations, with a thermal sensitivity (NETD) of 150 mK for the PI 450i G7 and 80 mK for the PI 640i G7. This high level of precision allows manufacturers to prevent defects such as warping or premature breakage. The CTlaser 4ML glass breakage sensor further enhances the system’s reliability by immediately detecting any glass fractures during the tempering process, triggering protective measures to safeguard the equipment​.

The BUGIS 450i G7 and BUGIS 640i G7 systems stand out because they operate without the need for additional cooling or air purging, making them cost-effective and easy to maintain. Their compact design enables seamless integration into existing production lines, and the systems can be retrofitted into older tempering machines, enhancing their functionality without extensive modifications. The Digitally Controlled Lens Protection (DCLP) system also ensures that the cameras remain protected from falling glass, minimizing downtime and maintenance costs.

The high resolution, robust glass breakage detection, and easy integration make these systems the preferred choice for glass manufacturers. They offer precise, reliable, and cost-effective temperature control solutions that improve product quality, reduce defects, and streamline production processes. By utilizing advanced infrared technology, the PI 450i G7 and PI 640i G7 systems ensure that the single-pane safety glass production process meets the highest efficiency and safety standards.

Recommended Products

Other Glass Applications

Talk to us about your IR Temperature Measurement Requirements

There are over 300 different pyrometer variants to choose from in the Optris infrared pyrometer portfolio each optimized for material, spot size, distance from the target, and environmental conditions. Fortunately, there is a trained engineer to phone or chat with to guide you through the process of choosing the perfect infrared sensor for your application.

The same support is available for the extensive IR camera product line.