IR Cameras & Pyrometers for Solar Industry

Precision Temperature Monitoring for Solar Panel Manufacturing

The Role of IR Non-Contact Temperature Measurement for Solar Industry

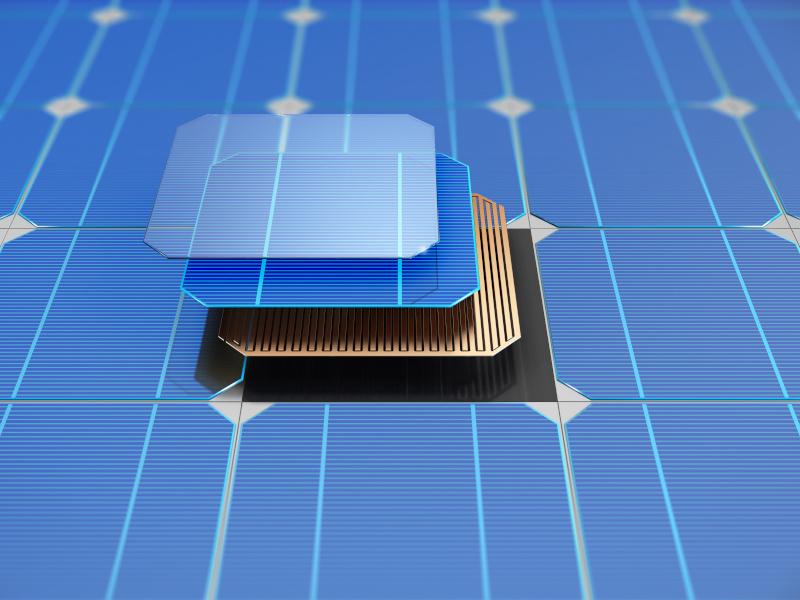

Infrared (IR) temperature measurement is crucial in the solar industry for enhancing the efficiency and quality of solar panel production. Key applications include solar cell flashers and steady state thermographic inspection of solar modules, which are essential for ensuring the reliability and performance of solar panels.

Solar cell flashers use IR technology to test the thermal response of solar cells under simulated sunlight. This process, known as illumination lock-in, helps identify temperature-related issues that could affect the efficiency of the solar cells. Accurate temperature measurement during this phase ensures that the cells are functioning optimally and can perform effectively in real-world conditions.

In solar module manufacturing, IR cameras and pyrometers are employed to monitor the temperature of solder strings and other critical components. Maintaining precise temperature control during the soldering process is vital to avoid defects that could compromise the integrity and performance of the solar modules.

Steady state thermographic inspection further ensures the quality of solar panels by detecting potential hot spots and thermal anomalies that may lead to premature failure. By integrating IR temperature measurement throughout the manufacturing and testing phases, manufacturers can enhance solar panel performance, reduce defect rates, and ensure long-term reliability in solar energy systems.

Solar Applications

Challenges of IR Non-Contact Temperature Measurement in the Solar Industry

Infrared (IR) non-contact temperature measurement in the solar industry encounters several key challenges that can impact its ability to enhance quality effectively. One major issue is emissivity variation among the diverse materials used in solar module manufacturing. Components like solder strings and different layers within solar panels have varying emissivity values, which necessitates precise calibration of IR sensors. Incorrect emissivity settings can lead to inaccurate temperature readings, potentially compromising the performance and reliability of the solar panels.

Thermal gradients within solar modules also pose a significant challenge. During steady-state thermographic inspection, achieving accurate temperature uniformity is critical for detecting potential hot spots and thermal anomalies. Variations in temperature due to uneven heating during the manufacturing process can be difficult for standard IR sensors to detect, making it challenging to maintain consistent quality throughout the entire module.

Another challenge is ambient heat interference. In procedures such as illumination lock-in with solar cell flashers, the heat emitted by surrounding equipment and environmental factors can distort IR measurements. To ensure accurate temperature readings, it is essential to implement proper shielding and strategic placement of IR sensors to mitigate these interferences and obtain reliable data.

Benefits of Using IR Non-Contact Temperature Measurement in Solar Modules Production

Despite the challenges, IR non-contact temperature measurement offers substantial benefits for enhancing quality in the solar industry. One of the primary advantages is precise temperature control during the solar module manufacturing process. By using IR cameras and pyrometers, manufacturers can closely monitor and manage temperatures during critical stages, such as the soldering of solder strings. This precision helps prevent defects and ensures the integrity and performance of solar panels.

Steady-state thermographic inspection is another key benefit. IR technology allows for comprehensive thermal imaging of solar modules, identifying potential hot spots and thermal irregularities that could lead to premature failure. Early detection of these issues helps improve the overall quality of the solar panels and ensures their long-term reliability and efficiency.

In solar cell flashers, illumination lock-in with IR measurement enables accurate testing of solar cells under simulated sunlight conditions. This helps verify the cells’ thermal performance and efficiency, ensuring that they meet required standards before being integrated into modules. Enhanced quality control through IR technology leads to better-performing solar panels and more reliable solar energy systems.

Applications and Efficiency Gains

Integrating IR non-contact temperature measurement into the solar industry offers significant efficiency gains across various applications. During solar module manufacturing, real-time temperature monitoring and control help streamline the production process, reducing waste and improving overall efficiency. Accurate temperature management during the soldering process enhances product consistency and reduces the likelihood of defects.

In steady-state thermographic inspection, IR cameras provide detailed thermal profiles of solar modules, enabling manufacturers to identify and address issues before they impact product performance. This proactive approach to quality control helps minimize downtime and rework, leading to cost savings and improved production throughput.

Overall, IR non-contact temperature measurement supports energy efficiency and quality enhancement in solar panel production. By offering precise, real-time thermal data, IR technology helps optimize manufacturing processes, ensure high-quality products, and contribute to the development of more reliable and efficient solar energy systems.

What Is the Right Solution for My Needs?

Click here to find the product that suits your demands.

Talk to us about your IR Temperature Measurement Requirements

There are over 300 different pyrometer variants to choose from in the Optris infrared pyrometer portfolio each optimized for material, spot size, distance from the target, and environmental conditions. Fortunately, there is a trained engineer to phone or chat with to guide you through the process of choosing the perfect infrared sensor for your application.

The same support is available for the extensive IR camera product line.