Control PAN Stabilization During Precursor Oxidation with Infrared

Advanced Temperature Control Techniques for PAN Oxidation enhances Carbon Fiber Quality in Automotive Manufacturing

Challenge

Precise temperature control during PAN precursor oxidation is difficult in high-heat environments, yet crucial for producing consistent, high-quality carbon fiber while minimizing waste and rework.

Solution

Continuous, non-contact infrared temperature monitoring enables real-time adjustment of IR heaters, keeping the process within the optimal thermal range without interfering with heating systems.

Benefits

- Ensures consistent precursor stabilization for high-quality carbon fiber output

- Prevents overheating and underheating, reducing defects and material degradation

- Enables real-time process adjustments to maintain ideal temperature conditions

- Minimizes production waste and rework, improving operational efficiency

- Supports compliance with strict quality demands in automotive-grade carbon fiber

Optimizing Temperature Control During Oxidation of Precursor in the PAN Stabilization

Carbon fiber production begins with the creation of a polyacrylonitrile (PAN), derived from the polymerization of acrylonitrile monomers. Carbon fiber primarily comprises organic polymers featuring long molecular chains bonded by carbon atoms. Approximately 90% of carbon fibers are produced using the PAN process.

The early stages of production involve the transformation of the raw material, known as the precursor, into carbon fiber. This precursor, drawn into long strands of fiber and uniformly spread into a web before entering the oxidation phase. The precursor’s journey through these stages is a crucial part of the production process.

In the subsequent oxidation stage, the material changes color, signaling its approach to full oxidation. Once fully oxidized, the material is ready for carbonization, a process carried out in both low and high-temperature furnaces.

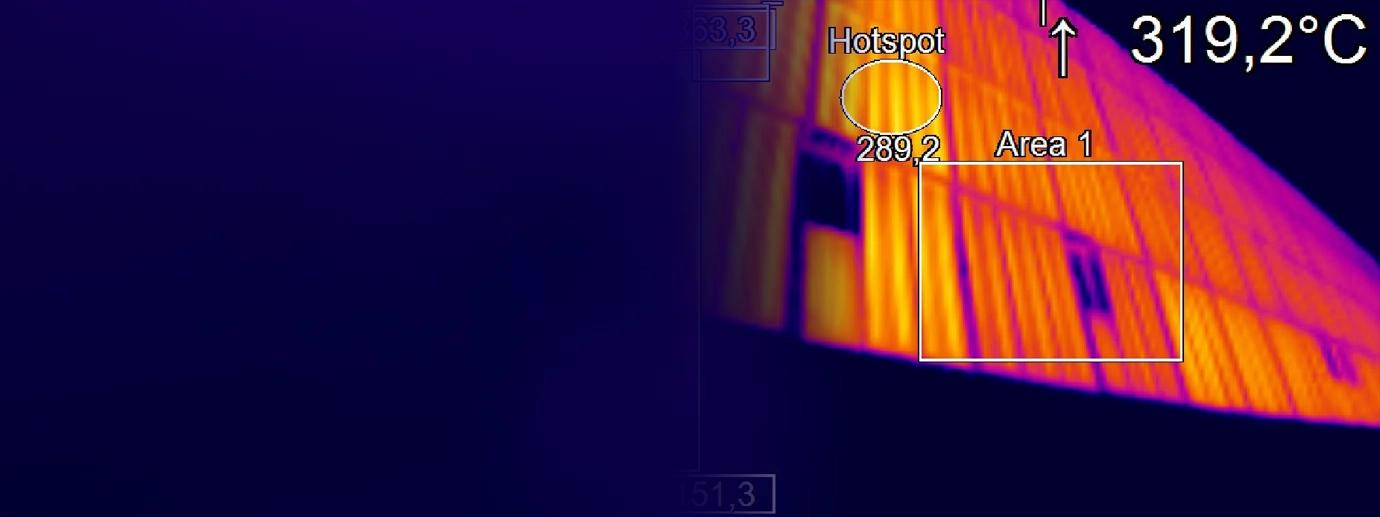

Stabilization involves crosslinking the polymer chains to prevent relaxation and chain scission during the subsequent carbonization. This process typically occurs in an air atmosphere at temperatures 200 to 300°C. The duration of this process depends on the fiber’s thickness, which usually lasts between two and four hours for PAN fibers.

After achieving full oxidation, the material is ready for the carbonization phase, which occurs in both low- and high-temperature furnaces.

One of the key challenges in this process is the precise control of temperature within the high-heat environment where these precursors are stabilized. This control is crucial to ensure a stable and repeatable production process, ultimately leading to high-quality carbon fiber components with minimal waste and rework. To address this challenge, infrared temperature measurement becomes essential, offering non-contact, accurate, and real-time data that plays a significant role in maintaining the required temperature levels.

Optimizing PAN Precursor Oxidation with Optris CThot LT’s High-Temperature Capabilities

Optris offers a comprehensive range of infrared solutions specifically designed to meet the demanding requirements of carbon fiber manufacturing. Among these, the CThot LT infrared thermometer stands out for its ability to operate accurately in high-temperature environments, withstanding ambient temperatures up to 250°C. The CThot LT is ideally suited for continuous temperature monitoring of precursors moving through infrared heating zones.

In this application, multiple CThot sensors are integrated into the machinery to measure the surface temperature of the materials. This precise measurement allows for optimizing the IR emitters’ heating power, ensuring consistent production quality. The IR heater utilizes short-wavelength infrared radiation, which is highly effective at quickly heating surfaces by penetrating a shallow depth into the material. In contrast, the CThot system operates using long-wavelength infrared radiation. Because these two systems function at different wavelengths, they do not interfere with each other. The short-wavelength IR heater efficiently targets specific areas for heating, while the long-wavelength CThot system provides accurate temperature measurements without being affected by the heater’s radiation. This distinction allows both systems to work simultaneously, maintaining their performance without compromise.

This continuous monitoring ensures that the temperature remains within the optimal range, preventing overheating and underheating, which could otherwise degrade the material’s properties. The analog output from these devices facilitates seamless integration with existing control systems, enabling real-time adjustments to the heating elements based on the precise temperature data collected.

Optris Infrared Technology Elevates PAN Stabilization to Meet Automotive Industry Standards

The implementation of Optris infrared technology in carbon fiber manufacturing has resulted in significant improvements in production consistency and product quality. By maintaining a stable and precise temperature throughout the manufacturing process, manufacturers have been able to reduce the amount of waste and rework, leading to cost savings and increased efficiency. The Optris solutions, known for their durability and accuracy in extreme environments, have proven to be a reliable choice for maintaining the stringent quality standards required in the automotive industry. Optris’s ability to offer solutions that can withstand high ambient temperatures and provide accurate, real-time data is a key differentiator in the market. Additionally, the user-friendly interface and ease of integration with existing systems make Optris the preferred partner for temperature measurement in carbon fiber production. The combination of precise temperature control, robust hardware, and comprehensive support from Optris ensures that manufacturers can consistently produce high-quality carbon fiber components.

Recommended Products

Other Automotive Applications

Talk to us about your IR Temperature Measurement Requirements

There are over 300 different pyrometer variants to choose from in the Optris infrared pyrometer portfolio each optimized for material, spot size, distance from the target, and environmental conditions. Fortunately, there is a trained engineer to phone or chat with to guide you through the process of choosing the perfect infrared sensor for your application.

The same support is available for the extensive IR camera product line.