Electrical Substation Monitoring with Radiometric Infrared Camera

Ensuring Power Grid Reliability with Continuous Thermal Monitoring Solutions

Challenge

Electrical substations face rising failure risks due to aging infrastructure, increasing energy demand, and infrequent manual inspections that miss transient faults. Limited workforce availability and safety concerns further hinder effective thermal monitoring, leaving critical issues undetected and threatening power reliability.

Solution

Continuous thermal monitoring with fixed infrared cameras enables 24/7 detection of abnormal temperature patterns in substations. This application ensures real-time fault identification, supports predictive maintenance, and reduces unplanned downtime by integrating thermal data into broader monitoring systems for timely and reliable decision-making.

Benefits

- Detects early-stage failures before they escalate into major outages or damage.

- Reduces unplanned downtime and extends substation equipment service life.

- Enhances personnel safety by minimizing the need for on-site inspections.

- Supports predictive maintenance strategies through reliable thermal trend data.

- Improves operational efficiency and grid reliability with round-the-clock thermal oversight.

Ensuring Power Stability, Preventing Equipment Failures, Reducing Costs and Downtime in Substations

Keeping distribution grids running is critical to sustaining our current way of life. Electrical transmission and distribution lines are crucial for linking power stations to consumers, and substations create extensive interconnections. Growing electricity demand and the rapidly changing load cases due to renewable energy put more strain on these electrical substations. This expansion increases the risk of equipment failures, compromising power reliability. Aging infrastructure and increased demand for low-cost energy have stressed substations and grids, increasing the risk of costly brownouts and blackouts so much that energy supply companies face increasing pressure. Reliable solutions are needed to increase capacity, maintain reliability, and control costs. Understanding the thermal distribution of substation components is critical, as electrical resistance causes degradation and energy dissipation as heat.

Traditional spot-check monitoring with handheld thermal imaging cameras is ineffective due to time and workforce limitations, not to mention safety risks. In addition, manual thermal camera inspections are infrequent, conducted only monthly at best, which risks undetected faults because field-based technicians with handheld infrared cameras can only perform periodic checks, which may miss transient problems or those that develop between inspections. This manual inspection of substation equipment is labor-intensive and prone to errors due to missed inspection spots, wrong settings, image blurring, or subject to the technician’s subjective interpretation of thermal images. A modern and innovative approach involves installing low-powered thermal cameras around substation equipment for continuous monitoring. These solutions allow remote monitoring, reducing downtime and costs associated with equipment failures. Despite higher initial costs, this approach improves reliability and reduces long-term expenses due to fewer power outages, equipment failures, and labor and maintenance costs.

Early Fault Detection with 24/7 Thermal Monitoring with Fixed Infrared Cameras

Fixed infrared cameras offer continuous monitoring, identifying potential failures early, improving reliability, and reducing maintenance costs. Permanently installed infrared cameras provide real-time data on the thermal profiles of critical components around the clock. This ensures that potential issues are detected early, regardless of time or conditions, significantly reducing the risk of sudden failures. The infrared cameras

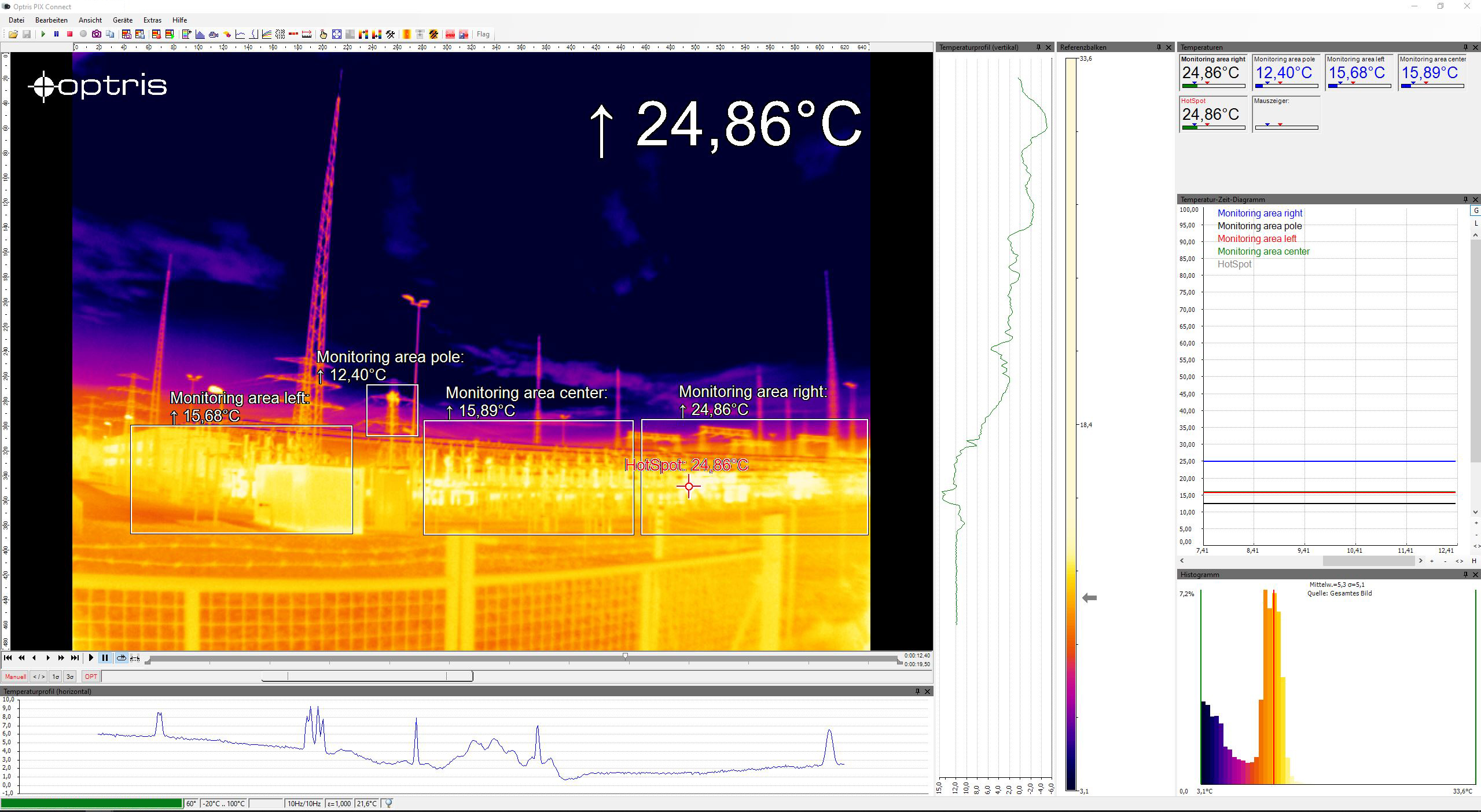

Strategically mounted infrared cameras provide the best measurement characteristics possible. These fixed cameras monitor the substation 24/7, deliver continuous thermal monitoring, enable the detection of anomalies, alarm critical issues, and provide trended data on asset status. User-selectable ROIs’ minimum, maximum, and average temperatures within the thermal image are calculated and trended. The temperature difference between ROIs is calculated to help normalize environmental conditions. These trends can be viewed along with the underlying infrared image and are easily shared.

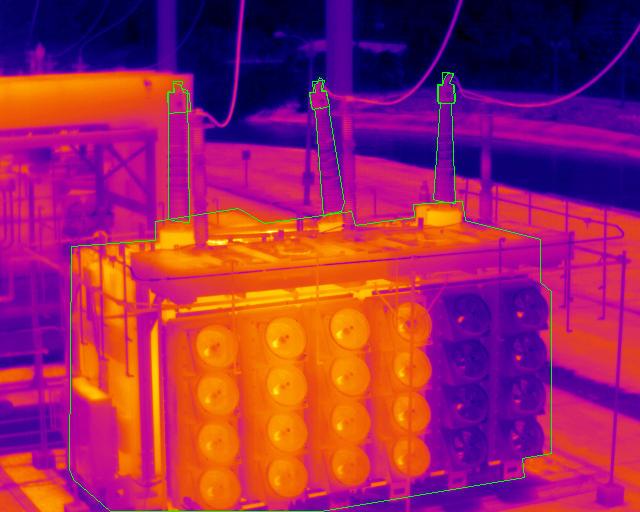

A few substation components whose thermal signatures are precursors to failure include power transformers (oil levels and pump operation), load tap changers (oil levels and other internal problems), insulator bushings (oil levels and bad connections), standoff insulators (moisture, contamination, and degradation), lightning arrestors (degradation of metal oxide disks), circuit breakers (oil or SF6 leakage), and mechanical disconnects (bad connections and contamination).

The Optris Xi 410 infrared camera is frequently utilized for its fast Ethernet interface and PoE, allowing for simple installation even over long distances. Its built-in hotspot finder function and autonomous stand-alone mode ensure continuous measurement and alarm functionality, maintaining reliability even if network connections are disrupted. The advanced thermal imaging capabilities of the Xi 410 allow utilities to understand the thermal profiles of critical components, identifying potential faults before they lead to failures.

Data from other sensors monitoring voltage, current, frequency, or visual cameras must be merged. Optris collaborates with Cutsforth, leveraging their InsightCM™ software platform to efficiently process and classify collected data. Optris Xi 80 and Xi 410 infrared cameras are fully compatible with InsightCM™, designed to monitor thermal images and temperature data from multiple camera inputs. The InsightCM™ platform integrates thermal camera data with OSI PI Historian, SCADA, CMMS, and other enterprise software environments.

Detecting Loose Connections and Malfunctioning Fans with Xi410 Infrared Cameras

At a large Midwest power generation facility, the need for early detection of reliability issues with transformers and switchgear assets was paramount. The implementation of Optris Xi410 infrared cameras significantly improved this process. These robust thermal cameras provided a rugged, edge-based solution for continuous infrared image acquisition, coupled with backend software for trending, alarming, and image review.

For instance, when monitoring a transformer, the tank temperature and the temperature of each bushing were continuously tracked and alarmed, with temperature values trending over time. Monitoring maximum and delta temperatures between the three phases identified a loose connection on the high line drop to the transformer. The plant also discovered loose busbar connections and loose connections on drops from HV lines to GSU bushings, which could lead to corona, heat buildup, and eventual arcing, potentially resulting in catastrophic failures.

The thermal surveillance solution further revealed that a third of the radiator fans were not functioning, risking transformer overheating, reduced performance and unit derate. Cleaning the radiators was necessary to enhance performance.

The Xi 410 infrared cameras were instrumental in identifying these issues, allowing for timely intervention and performance improvements. With their high accuracy and affordable price point, these industrial cameras significantly lower the initial cost of a comprehensive monitoring system.

Recommended Products

Other Condition Monitoring Applications

Talk to us about your IR Temperature Measurement Requirements

There are over 300 different pyrometer variants to choose from in the Optris infrared pyrometer portfolio each optimized for material, spot size, distance from the target, and environmental conditions. Fortunately, there is a trained engineer to phone or chat with to guide you through the process of choosing the perfect infrared sensor for your application.

The same support is available for the extensive IR camera product line.