IR Cameras & Pyrometers for Food Industry

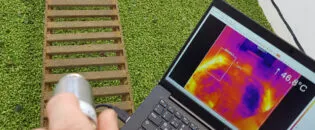

Advanced Thermal Imaging for Quality Control in Food Processing

Why IR Temperature Measurement is Important for the Food Industry

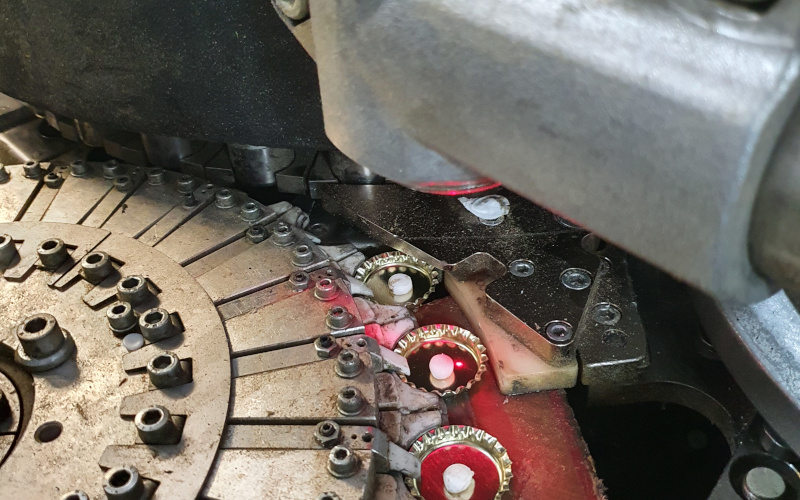

In the food industry, IR temperature measurement is crucial for maintaining high-quality standards and ensuring efficient processes. High-speed temperature measurement (within just 90 microseconds) provided by IR technology enables precise monitoring in the fast-paced food and packaging industries. For example, in the bottling process of beverages with crown corks, maintaining the correct temperature is essential to ensure proper sealing and extend shelf life.

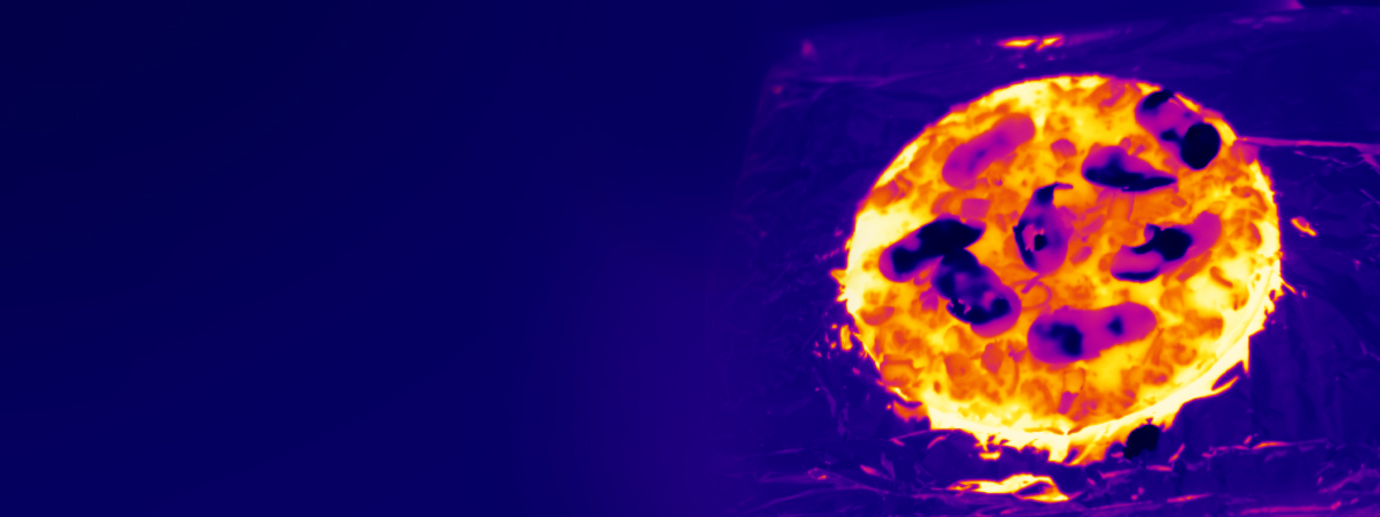

Additionally, non-contact temperature measurement allows accurate temperature monitoring of critical stages in food production, such as the spraying process for ice cream production. By accurately tracking temperatures, manufacturers can ensure that ice cream is processed at optimal temperatures, preventing issues like ice crystal formation and ensuring a smooth texture.

For applications like homogeneous hop drying in brewing, IR cameras offer real-time insights into temperature distribution across drying surfaces. This helps achieve consistent drying, essential for producing high-quality hops that meet stringent flavor and aroma standards.

Moreover, IR technology helps in maintaining consistent temperatures throughout the production line, reducing variability and enhancing overall product quality. By integrating IR pyrometers into various stages of food production, manufacturers can improve process control, ensure food safety, and optimize production efficiency, leading to better end products and higher consumer satisfaction.

Food Applications

Precision & High-Speed Monitoring

IR technology provides highly accurate temperature measurements without direct contact, ensuring precise control over critical food processing stages. This is crucial for maintaining quality and safety in production. IR sensors enable real-time temperature monitoring at high speeds, which is essential for processes such as high-speed food production and packaging. This capability helps in detecting temperature deviations immediately and making necessary adjustments.

Quality Control & Reduced Risk of Contamination

By monitoring temperature during key stages like cooking, drying, and cooling, IR technology ensures that food products meet quality standards. This helps prevent issues like undercooking or overheating, which can affect the taste, texture, and safety of the product. Non-contact IR measurement minimizes the risk of contamination since the sensors do not come into direct contact with food products. This is particularly important in maintaining hygiene and preventing contamination in food processing.

Energy Savings & Reduced Maintenance Costs

Accurate temperature monitoring helps optimize energy use in cooking, drying, and cooling processes. By ensuring that temperatures are maintained within the desired range, IR technology can contribute to energy efficiency and cost savings. Moreover, IR sensors are typically low-maintenance and have no moving parts, which reduces the likelihood of mechanical failures and the associated maintenance costs. This contributes to long-term operational efficiency and cost-effectiveness.

Versatility Across Applications

IR technology is applicable across a wide range of food processing activities, including cooking, baking, cooling, and packaging. This versatility makes it a valuable tool for various food industry applications. It also facilitates seamless integration into existing production lines, ensuring minimal disruption while enhancing operational efficiency. By adapting to different stages of food processing, IR technology helps optimize every phase, leading to improved overall performance and product quality.

What Is the Right Solution for My Needs?

Click here to find the product that suits your demands.

Talk to us about your IR Temperature Measurement Requirements

There are over 300 different pyrometer variants to choose from in the Optris infrared pyrometer portfolio each optimized for material, spot size, distance from the target, and environmental conditions. Fortunately, there is a trained engineer to phone or chat with to guide you through the process of choosing the perfect infrared sensor for your application.

The same support is available for the extensive IR camera product line.