Ensure Advanced Fire Safety in the Tortilla Chips Food Processing

Preventing Grease and Cooking Oil Fires in Industrial Kitchens

Challenge

The tortilla chip production process involves high-temperature frying, where chips exiting hot oil may carry residual grease capable of reaching autoignition temperatures. This creates a serious fire risk on the conveyor belt, exacerbated by the harsh, oil-contaminated environment that challenges traditional fire detection and monitoring technologies.

Solution

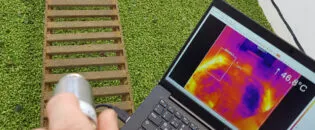

An thermal camera is installed top-down over the conveyor to continuously monitor chip temperatures after frying. By detecting hot spots in real time, the system enables early intervention before ignition can occur, while withstanding the greasy and harsh conditions typical of food processing environments.

Benefits

- Detects fire risks early before visible smoke or flames develop

- Reduces production downtime by preventing fire-related interruptions

- Enhances safety for personnel, equipment, and product quality

- Operates reliably despite oil and grease contamination in the environment

- Enables real-time thermal data integration for automated safety responses

Fire Risks in Commercial Kitchen Associated with Frying in Oil and Grease

The industrial processing of tortilla chips is a complex operation, requiring precise coordination across various steps to ensure a consistently high-quality product. One of the most critical stages is frying the chips in hot oil, typically maintained at approximately 170°C. The chips are immersed in this oil for only about one minute before being transferred onto a conveyor belt for the next stage of processing.

This part of the process presents unique challenges, particularly concerning the temperature of the chips as they exit the oil bath. When the chips are removed from the oil, they are still extremely hot and saturated with oil, creating a potential risk of overheating. If the chips become excessively hot, they could pose a significant hazard, including the possibility of ignition on the conveyor belt. Cooking grease can spontaneously combust if it reaches its autoignition temperature without the need for an external flame or spark.

Grease fires are particularly dangerous because they burn at much higher temperatures than typical fires involving wood or other materials, making them more intense and challenging to extinguish. In fact, about 50% of all accidental fires in hotels, restaurants, and fast-food establishments originate in kitchens, often due to cooking oil or fat fires. The temperature of cooking oil fires can reach up to 400°C, with autoignition temperatures ranging from 285°C to 385°C. If the grease on the chips reaches this critical temperature range, it can ignite, posing a severe fire risk that must be managed to prevent damage to products, personnel, and machinery.

To mitigate this risk, the food producer is seeking to install a reliable early warning system that can automatically detect potential fire hazards on the conveyor belt and trigger an alarm in the event of a fire. Another challenge in this environment is the harsh conditions for technical measuring devices. The likelihood of these devices becoming contaminated with oils and fats is high, necessitating the use of exceptionally robust instrumentation equipment that can withstand these demanding conditions.

Preventing Fires in Food Production: How Infrared Camera Systems Offer Early Detection

There are four primary types of fire detection devices: smoke detectors, heat detectors, flame detectors, and gas detectors. Each type varies in detection timing and sensitivity, depending on the underlying technology. Some sensors are highly sensitive and capable of detecting fires in their early stages, while others may only trigger an alert after the fire has spread significantly. Understanding the effectiveness of each type of fire detection sensor at different stages of fire development is crucial for facility managers when choosing the most appropriate system for their needs.

Infrared camera systems stand out for their ability to provide the earliest possible warnings. These cameras can detect the subtle warming of materials well before smoke particles or flames are even visible, as they operate based on the principle of heat radiation. This early detection capability makes infrared cameras particularly valuable for preventing fires before they can escalate.

The food producer found the perfect fitting device for his application: the Xi 400 from Optris. To address the fire risk during tortilla chips production, the infrared camera Xi 400 was installed at the oven outlet, positioned top-down over the conveyor belt. This installation allows the thermal camera to monitor the entire conveyor width, ensuring that any hot spots—temperatures exceeding 100°C—are immediately detected. The Optris infrared camera solution provides comprehensive monitoring, capturing the complete thermal profile of the chips as they exit the fryer, which is crucial for identifying non-uniform heating that could lead to fires.

One significant advantage of using an infrared camera is monitoring multiple production lines or conveyor belts simultaneously with a single infrared imager. The infrared camera’s capability to provide consistent and accurate temperature readings across the conveyor ensures that any potential fire hazards are quickly identified.

To accommodate the harsh conditions of the production environment, Optris also provided accessories such as an air purge system to keep the camera lens clean and free from oil and fat buildup.

Integrating the Optris Xi 400 Infrared Camera in High-Risk Production Environments

In recent years, early fire detection systems that utilize infrared cameras have gained widespread popularity due to their proven effectiveness in enhancing fire prevention and safety. By detecting potential fires at the earliest stages, infrared cameras provide facility managers with critical early warnings, allowing for swift responses that minimize potential damage.

In the context of tortilla chip production, the implementation of the Optris Xi 400 infrared camera has significantly bolstered fire safety. This system delivers precise temperature measurements across a wide area, ensuring the early detection of hot spots and reducing the risk of fire incidents. With a high thermal sensitivity of 50 mK, the camera is capable of detecting even the smallest temperature fluctuations, making it an indispensable tool for maintaining both safety and efficiency in the production process.

Customers who have integrated the Xi 400 into their operations have reported substantial benefits, including reduced production downtime and lower maintenance costs. These improvements stem from the camera’s ability to prevent fires before they can ignite. The Xi 400’s robust design, featuring an IP67-rated enclosure, ensures reliable performance even in the challenging conditions typical of food production environments. Additionally, the included PIX Connect software offers advanced image processing capabilities, such as line scan features that provide detailed thermal profiles of the production line, further enhancing monitoring accuracy.

Key features of the Xi 400 include its compact size, motorized focus, high optical resolution, and the critical automated hot spot detection function, all of which deliver exceptional precision and reliability for applications like tortilla chip production.

Moreover, the infrared camera’s data can be seamlessly integrated with a Programmable Logic Controller (PLC), enabling real-time and automated control of heat distribution. This integration further strengthens fire prevention measures, providing an additional layer of safety and control in the production environment.

Recommended Products

Other Food Applications

Talk to us about your IR Temperature Measurement Requirements

There are over 300 different pyrometer variants to choose from in the Optris infrared pyrometer portfolio each optimized for material, spot size, distance from the target, and environmental conditions. Fortunately, there is a trained engineer to phone or chat with to guide you through the process of choosing the perfect infrared sensor for your application.

The same support is available for the extensive IR camera product line.