Ice Cream Cone Production: Integrating Optris Infrared Technology for Food Quality Monitoring

Automate and Optimize Chocolate Coating in Ice Cream Cone Production with DewesoftX Software

Challenge

Inconsistent chocolate spraying during cone production leads to uneven coating, product rejects, and unnecessary waste. Malfunctions like blocked nozzles or poor spray pressure go undetected, compromising quality and increasing production costs in a high-speed, automated environment.

Solution

The thermal imaging system monitors chocolate spray temperature in real time, detecting uneven distribution and nozzle malfunctions. Integrated into the production line, it enables automatic removal of defective cones and ensures consistent coating through continuous thermal analysis.

Benefits

- Reduces waste by identifying and removing non-conforming cones in real time

- Ensures consistent chocolate coverage across all cones, improving visual and taste quality

- Enhances production efficiency through reliable, continuous thermal monitoring

- Supports full automation with seamless integration into existing production systems

- Enables early detection of spray system issues, minimizing downtime and maintenance effort

Minimizing Waste and Maximizing Quality in Ice Cream Cone Production

An international ice cream manufacturer seeks to enhance the quality of its chocolate spraying process and automate the entire ice cream cone production line. With operations in over 20 countries, the company is a leading international distributor, offering various ice cream products, from classic cones to tubs and beyond.

In an automated ice cream cone production process, equipment mixes large batches of the mixture, ensuring consistent quality. Industrial freezing equipment maintains a continuous and efficient freezing process. Specialized machines mold the frozen mixture into cone shapes, while others sprinkle additional ingredients, such as chocolate or cream, onto or into the cones. Automated quality control measures ensure that each ice cream cone meets shape, size, texture, and flavor standards. Finally, automated systems package the ice cream cones into containers or wrappers at high speed.

Many cones are covered with liquid chocolate during production, and various problems can occur during coating. During production, various problems can occur during the coating process. Incorrect machine settings can result in reduced spray pressure, leading to inadequate chocolate distribution. Material build-up can block nozzles, causing insufficient or no chocolate to be sprayed. Temperature fluctuations can affect the quality of the chocolate coating and the overall product. These issues can lead to high reject rates, resulting in significant waste and increased production costs. Automated quality control measures are essential to detect and address these problems promptly.

Pieces that do not meet quality standards are typically disposed of as waste. A machine malfunction generating non-conforming pieces can have significant implications for a company producing an ice cream cone every 1.5 seconds. If only 1% of the ice creams produced fail to meet standards, this results in 24 non-conforming pieces per hour. Over a 24-hour cycle, this amounts to 576 discarded ice creams daily. No company can afford such waste.

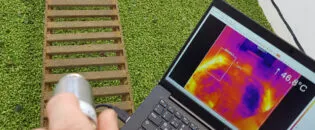

Infrared Camera Xi 400 Delivers the Thermal Input for the DEWESoft Software

This advanced system utilizes an Optris Xi 400 thermal imaging camera, seamlessly integrated with DewesoftX software. The infrared camera connects via the Dewesoft Optris plugin, a software module that provides comprehensive data visualization, analysis, and storage support for various Optris thermal imaging cameras, including the Xi 400, PI 400i, and PI 640i models. The system specifically tests the efficiency of the chocolate spraying process, significantly improving product quality and automating the entire procedure.

A single thermal imaging camera with a resolution of 302 x 288 pixels is used to conduct these tests. Positioned at an elevated point above the production line, the camera captures crucial parameters for analyzing the quality of chocolate spraying on one of the six rows of cones at a time. The lens points downward to record the edges and inner areas of the wafers, ensuring precise data collection.

The DEWESoft solution records and compares average maximum and minimum temperature values. If the maximum value is too low and the minimum value too high, this indicates uneven chocolate spraying and potential nozzle issues. By continuously measuring and comparing the current temperature values of the ice cream cones, the system detects non-conforming parts. A specialized machine within the production process then automatically removes these defective parts, maintaining high product standards.

Accurate Thermal Data Collection and Easy Implementation with DEWESoftX

The Optris Xi 400 thermal imaging camera is selected for its robust and compact design, combining the durability of a pyrometer with the advanced functionalities of an infrared camera. Optris infrared cameras are perfect for system solutions that require quick and reliable temperature monitoring and the ability to trigger subsequent actions, such as alarms or automatic production line shutdowns.

These cameras are compact, robust, and adaptable, making them suitable for challenging industrial environments when used with available accessories. They integrate easily into existing processes and applications.

DEWESoft is utilized in the automation of the ice cream production line due to its advanced DewesoftX software, which offers comprehensive data visualization, analysis, and storage capabilities. The software seamlessly integrates with the Optris Xi 400 thermal imaging camera, enabling precise temperature monitoring and control. This integration allows for real-time detection of irregularities in the chocolate spraying process, ensuring consistent product quality. The robust and user-friendly solution enhances automation, predictive maintenance, and process optimization, significantly reducing waste and improving operational efficiency. Its adaptability to existing systems makes it an ideal choice for this application.

Recommended Products

Other Food Applications

Talk to us about your IR Temperature Measurement Requirements

There are over 300 different pyrometer variants to choose from in the Optris infrared pyrometer portfolio each optimized for material, spot size, distance from the target, and environmental conditions. Fortunately, there is a trained engineer to phone or chat with to guide you through the process of choosing the perfect infrared sensor for your application.

The same support is available for the extensive IR camera product line.