Infrared Temperature Measurement of Food in Commercial and Industrial Kitchens

Preventing Fire Hazards and Ensuring Food Quality in Industrial Kitchens with Noncontact Temperature Monitoring

Challenge

Industrial kitchens face risks of undercooked food, overheated oil, and potential fire hazards due to inconsistent temperature control and contamination concerns in high-heat, grease-filled environments.

Solution

Infrared cameras enable precise, contactless temperature monitoring of cooking surfaces and oils, ensuring reliable thermal control and early detection of hazards without contamination.

Benefits

- Prevents oil from exceeding safe temperature, reducing fire risks in kitchens

- Ensures uniform cooking for consistent food quality and safety compliance

- Minimizes contamination by avoiding physical contact with food or surfaces

- Enables early anomaly detection for proactive kitchen process control

- Reduces waste and energy use through optimized cooking temperature management

Overheated Oils and Undercooked Food: The Importance of Temperature Management in Industrial Kitchens

Temperature control in industrial cooking is essential for ensuring food safety, quality, and consistency. Precise temperature regulation prevents undercooking or overcooking, reducing the risk of foodborne illnesses and maintaining the desired texture, flavor, and appearance of the final product. This ensures uniform quality that meets industry standards and consumer expectations. Additionally, optimal temperature control enhances energy efficiency and minimizes waste, contributing to cost savings and environmental sustainability. In industrial settings, automated systems and advanced sensors are employed to achieve accurate and consistent temperature management.

Temperature sensors must not contaminate the food. Food-grade materials, such as stainless steel, are used to manufacture these sensors, ensuring they are non-reactive and easy to sanitize. Non-contact sensors, like infrared thermometers, can measure temperature without direct contact, reducing contamination risks.

Condition monitoring of food and cooking oil is crucial for the quality of prepared dishes. Temperature control of oils, in particular, plays a central role. If oil exceeds 200 °C, it must be replaced, as overheated fat can negatively affect the taste of food due to chemical composition changes, potentially leading to undesirable flavors and harmful compounds.

A lack of temperature control can result in uneven heating of cooking surfaces, causing unpredictable cooking times and unevenly cooked food. Implementing accurate monitoring and control systems minimizes this issue. Additionally, temperature monitoring is essential for preventing fire hazards. Overheated oils and fats can easily catch fire, posing risks to the kitchen and employees.

Enhancing Fire Safety and Food Quality with Infrared Cameras in Commercial Kitchens

Non-contact temperature sensors, such as infrared thermometers, measure temperature without direct contact, reducing the risk of contamination.

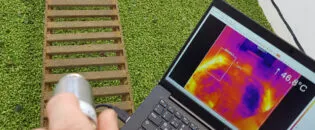

For the food industry, the Optris Xi 400 infrared camera offers an excellent solution. It can be easily mounted inside a kitchen using a bracket and aligned to the relevant measurement objects. The motorized focus allows installation at a distance from the heat source, such as a stove or grill.

The Xi 400 infrared camera measures oil temperature in pans and sends an alarm signal if the oil exceeds 200 °C. This significantly reduces the risk of fire and ensures the quality of prepared food.

The Xi 400 is an industrial camera with 382 x 288 pixels for precise temperature measurements from -20 °C to 900 °C. It boasts an excellent optical resolution with a spot-to-distance ratio of up to 390:1. Its 80 Hz frame rate for monitoring fast thermal processes quickly and reliably detects anomalies in the preparation process or potential fire hazards. These features make the Optris Xi 400 ideal for industrial or commercial kitchens.

The Optris PIX Connect software allows the creation of flexible measuring fields, enabling separate detection and analysis of multiple heat sources. The Xi 400 camera connects easily to a PC via USB, simplifying the setup of the monitoring system.

Robust Solutions for Industrial Kitchens: Optris Accessories for Harsh Environments

Infrared cameras used in industrial and commercial kitchens must be robust against external influences such as steam, smoke, grease particles, and splashes that are common in these environments. These external factors can significantly impact temperature measurements or even render them impossible, as well as contaminate the camera optics and degrade measurement accuracy.

To mitigate these issues, Optris offers numerous accessories to enhance the resistance and efficiency of the Xi series cameras. For instance, the water-cooling housing allows the cameras to operate effectively in hot environments. An air purge attachment and/or a shutter protect the camera optics from grease and dirt particles, ensuring a clear view of the measurement object.

The Xi 400 camera is also designed for easy integration. With a USB server Gigabit 2.0 and PoE adapter, the camera can connect to a PC over longer distances using PIX Connect. The Xi 400 can also interface with an industrial PIF and be controlled via a PLC, facilitating quick and easy integration into existing systems.

Recommended Products

Other Food Applications

Talk to us about your IR Temperature Measurement Requirements

There are over 300 different pyrometer variants to choose from in the Optris infrared pyrometer portfolio each optimized for material, spot size, distance from the target, and environmental conditions. Fortunately, there is a trained engineer to phone or chat with to guide you through the process of choosing the perfect infrared sensor for your application.

The same support is available for the extensive IR camera product line.