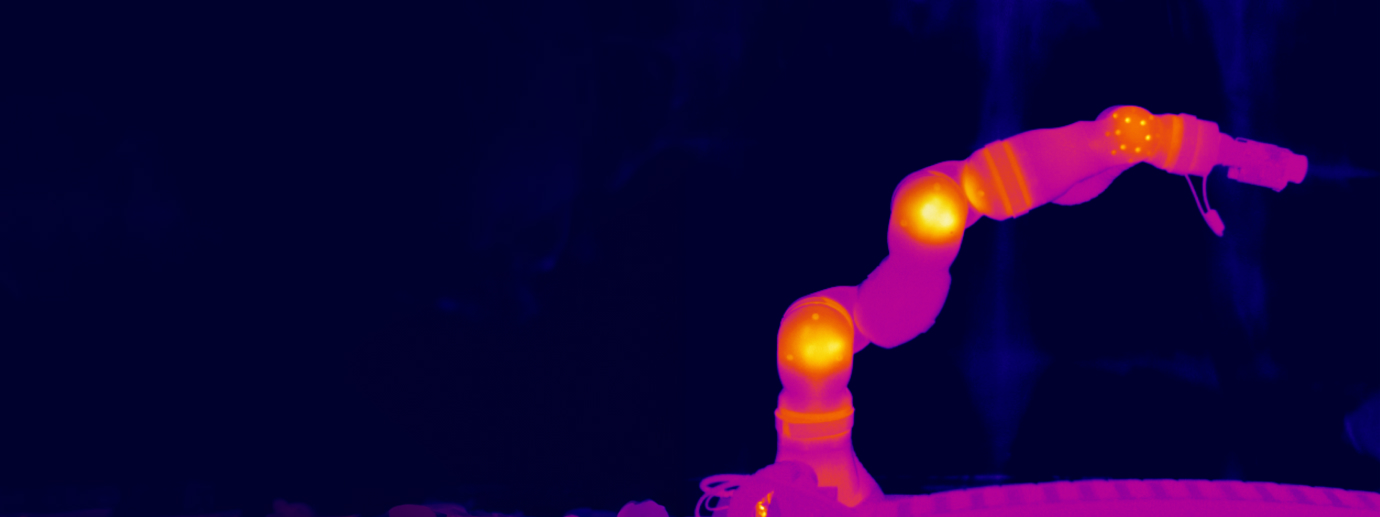

IR Cameras & Pyrometers for General Manufacturing

Enhancing Quality Control and Compliance with Non-Contact IR Sensors

How IR Temperature Measurement Drives Quality in Diverse Manufacturing Sectors

In general manufacturing, IR temperature measurement plays a crucial role in ensuring optimal production processes and maintaining high product quality. For industries like automotive, aerospace, and electronics, precise temperature control is essential. In adhesive applications, accurate monitoring of adhesive placement and curing ensures strong bonding and avoids defects that could compromise the final product.

IR cameras and pyrometers help prevent overheating and insufficient drying of coatings and paints by providing real-time temperature data. This is vital in applications where proper curing is critical, such as in automotive paint shops or aerospace component finishing. Effective temperature measurement avoids issues like blistering or uneven finishes, which can lead to costly rework and reduced product durability.

Additionally, in manufacturing processes like garden hose production, and the production of PVC or rubber products, IR temperature measurement ensures that materials are heated and processed uniformly. This helps prevent defects, ensures consistent quality, and enhances overall efficiency.

Overall, IR temperature measurement is essential for monitoring and controlling temperatures across various manufacturing applications. It enhances process control, improves product quality, and reduces the risk of defects, making it a valuable tool for achieving operational excellence in general manufacturing.

General Manufacturing Applications

Enhanced Process Control & Quality Assurance

IR sensors provide precise, real-time temperature readings, allowing for tight control over manufacturing processes. This is crucial in applications such as adhesive curing, where accurate temperature monitoring ensures optimal bonding and prevents defects.

Accurate temperature measurement helps maintain high product quality by ensuring that components are processed at the correct temperatures. This is essential in sectors like automotive, aerospace, and electronics, where product reliability and safety are paramount.

Efficiency Improvements & Enhanced Safety

By monitoring temperature in real-time, manufacturers can identify and address issues promptly. This reduces the likelihood of process deviations, minimizes waste, and improves overall production efficiency.

Accurate temperature measurement with IR technology contributes to a safer manufacturing environment by detecting potential hazards before they escalate. This is particularly important in high-temperature processes where safety risks are higher.

Prevention of Overheating & Cost Savings

IR technology helps prevent overheating in critical processes such as coating and paint drying. By detecting excessive temperatures early, manufacturers can avoid potential damage to products and equipment, reducing the need for costly rework.

Additionally, IR sensors reduce the need for manual inspections and downtime by providing continuous, automated temperature monitoring. This leads to cost savings through more efficient use of resources and fewer production interruptions.

What Is the Right Solution for My Needs?

Click here to find the product that suits your demands.

Talk to us about your IR Temperature Measurement Requirements

There are over 300 different pyrometer variants to choose from in the Optris infrared pyrometer portfolio each optimized for material, spot size, distance from the target, and environmental conditions. Fortunately, there is a trained engineer to phone or chat with to guide you through the process of choosing the perfect infrared sensor for your application.

The same support is available for the extensive IR camera product line.