Glass Gob Production Control with Fixed Radiometric Infrared Cameras

Accurate Temperature Control and Real-Time Position Tracking in Industrial Glass Gob Production

Challenge

Glass gob processing suffers from inconsistent temperatures and positioning during transport, leading to deformation, stress, or defects in the final product. Ensuring uniform viscosity, controlled cooling, and accurate gob placement is difficult due to mechanical influences and dynamic thermal conditions in the high-temperature production environment.

Solution

By continuously monitoring both temperature and position with infrared cameras, operators gain real-time feedback on each gob. This enables early detection and correction of anomalies, reduces manual adjustments, and supports automation of gob transport and forming, improving process reliability and consistency throughout the production line.

Benefits

- Prevents gob deformation by ensuring consistent temperature during transport

- Reduces glass stress and defects through optimal gob cooling control

- Enables precise gob placement for improved forming accuracy and symmetry

- Supports early detection of process anomalies for quick corrective action

- Enhances production automation, reducing operator workload and manual adjustments

Addressing Temperature and Quality Challenges in Glass Gob Processing

The production of container glass, particularly glass bottles and jars, is a highly automated and energy-intensive process that requires extremely high temperatures. The process begins with raw material preparation, where the primary ingredients—sand, soda ash, limestone, and recycled glass—are mixed in specific proportions to achieve the desired glass composition. This mixture, known as the batch, is then transported to a melting furnace.

The melting furnace operates at approximately 1500 °C, where the batch is melted and processed into a homogeneous glass mass. Once the glass mass reaches the appropriate consistency, it is directed to a feeder, which forms the glass into drop-shaped portions called gobs. These gobs, the precursors to the final glass containers, are cut at precisely calculated intervals and transferred to the forming machine, a critical step in shaping the glass.

Several challenges can arise during the production of glass gobs, affecting the quality of the final product. One such challenge is the inhomogeneity of the glass batch. If the batch is not thoroughly mixed or unevenly melted, varying viscosities and temperature distributions can occur within the glass mass, leading to an inferior product.

Temperature control is crucial throughout the production process. A common issue is insufficient cooling of the gobs before molding. If the gobs are too hot, they become overly liquid and fail to maintain the desired shape during molding, resulting in deformations that compromise the optical quality and mechanical properties of the final product. Conversely, cooling the gobs too quickly can induce stresses in the glass, which may lead to cracks or fractures later on.

Mechanical influences during the transportation of the gobs to the forming machine can also pose problems. Exposure to external forces or displacements during this phase can deform or damage the gobs before they reach the forming machine, negatively impacting surface quality and structural integrity.

To avoid scrap and ensure high-quality production, it is essential to continuously and reliably monitor the position and temperature of the glass gobs throughout the process.

Infrared Camera Measures Glass Temperature and Position of Gobs

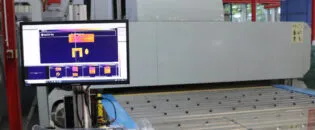

In this application, the Optris solution for monitoring glass gobs is the infrared camera PI 1M. This industrial, high-speed camera enables continuous and reliable monitoring of very hot and fast processes.

To monitor the position and temperature of the gobs, two PI 1M cameras are installed to cover both the X- and Y-axis of the glass gobs during their transport from the feeder to the forming machine.

The PI 1M infrared camera allows operators to accurately read the position and temperature of each glass gob, preventing issues such as the glass gob hitting the mold’s side wall. This reduces asymmetric temperature loss and results in higher quality bottles or other glass products. Additionally, the temperature of each gob can be recorded and saved, allowing for the quick detection and correction of temperature anomalies.

Using the free PIX Connect analysis software, measuring fields can be defined and permanently monitored. If there are any shifts in the transport path due to machine influences, the system can either inform the operator immediately or automatically correct the issue. This information can be communicated in various ways, such as through an alarm linked to the software or digital communication with the machine’s controller.

Regular manual adjustments of the gob guidance are necessary. However, automated position detection and adjustment with the PI 1M camera and PIX Connect Software support the operator, allowing them to focus on other parameters.

The process can be further automated using the PI 1M camera and PIX Connect software. The precise positioning of the glass gobs is achieved by using two PI 1M cameras positioned at a 90° angle, providing accurate x-y coordinates. With this information, the machine can automatically readjust the position of the glass gob without manual intervention from the operator.

Automating Glass Gob Production through Optris PI 1M’s Shortwave Characteristic and Speed

The primary advantage of using Optris infrared cameras for glass gob monitoring is their ability to automate the entire process easily. The short-wavelength characteristic ensures accurate temperature measurement of glass gobs, while the camera’s speed enables precise tracking and localization.

Many measurement objects made of non-shiny materials exhibit high and relatively constant emissivity, regardless of their surface consistency, especially in long-wave spectral ranges. However, metallic and shiny materials often have low emissivity at long infrared wavelengths. This low emissivity in the long wavelength infrared bandwidth can lead to varying and unreliable measuring results. The spectral range of the short wavelength PI 1M infrared camera aligns with the highest emissivity of most metallic materials, simplifying remote temperature measurement. According to Planck’s radiation law, exponentially more infrared radiation is emitted in the short wavelength range. As a result, linear emissivity issues have less influence on the repeatability of temperature measurement results at short wavelengths. This enhances the reliability and accuracy of temperature measurements, particularly for glass materials, when using the PI 1M infrared camera.

The PI 1M’s robust and compact design makes it ideal for use in tough and harsh environments, allowing for quick and easy installation. Additionally, Optris offers various accessories, such as a laminar air purge and the Optris Cooling Jacket. The air purge system maintains clean camera optics by employing airflow, preventing dust, smoke, and other particles from obstructing the view or contaminating the optics. The cooling jacket is a protective housing cooled by water, making the camera suitable for operating temperatures up to 315 °C.

The PI 1M infrared camera offers more than just high-resolution thermal imaging capability; it also excels at capturing temperature data across an extensive range, from 450°C to 1800°C, without sub-ranges. Its remarkable distance-to-spot-size ratio ensures accurate temperature measurements, even when capturing images from considerable distances. The infrared camera offers versatile frame rates and sub-image options to accommodate various application requirements. Operating at a resolution of 764 x 480 pixels, it runs at 32 Hz, ensuring detailed imaging. Switching to 382 x 288 pixels increases the frame rate to 80 Hz, which is ideal for capturing fast-moving objects with clarity. It can operate at 1 kHz with a resolution of 72 x 56 pixels for rapid applications, such as monitoring temperature changes.

Integration into industrial processes is seamless with the PI cameras, which can be connected via the Optris USB server, Optris PI NetBox, or an industrial process interface for process control. This flexibility allows the camera to be installed at a greater distance and the process to be monitored remotely. For instance, remote configuration via web-based management is possible with the USB server.

These features collectively ensure that Optris infrared cameras provide reliable and efficient solutions for monitoring glass gobs in various industrial settings.

Recommended Products

Other Glass Applications

Talk to us about your IR Temperature Measurement Requirements

There are over 300 different pyrometer variants to choose from in the Optris infrared pyrometer portfolio each optimized for material, spot size, distance from the target, and environmental conditions. Fortunately, there is a trained engineer to phone or chat with to guide you through the process of choosing the perfect infrared sensor for your application.

The same support is available for the extensive IR camera product line.