Infrared Temperature Monitoring in Disinfection and Sterilization for Enhancing Vaccine Vial Safety

Monitoring Tempered Vials for Medications, Insulin, and Vaccines to Ensure Decontamination

Challenge

Ensuring precise, contamination-free temperature monitoring of rapidly moving glass vials during disinfection, sterilization, and cooling is critical. Conventional sensors fail to detect vial temperatures directly, risking improper sterilization, especially with tight process timing and the need for accuracy across varying temperature zones.

Solution

Non-contact infrared temperature monitoring enables real-time, contamination-free tracking of each vial’s temperature throughout sterilization and cooling. Stationary thermal cameras above the vial path detect even slight deviations, aided by the cavity effect for accurate glass temperature measurement, ensuring control and traceability during high-speed pharmaceutical production.

Benefits

- Ensures each vial meets sterilization requirements before filling begins.

- Prevents contamination by eliminating contact during temperature measurement.

- Detects and removes incorrectly cooled or overheated vials automatically.

- Supports regulatory compliance with accurate, traceable thermal documentation.

- Optimizes yield and reduces rejects in high-speed pharmaceutical workflows.

Thermal Disinfection and Sterilization Checks Requires Tight Temperature Monitoring in Pharmaceutical Industry

Thermal disinfection, a critical process in the healthcare industry, is a highly reliable method that effectively reduces germs on temperature-resistant hard and exterior surfaces. Most harmful germs, viruses, and bacteria are sensitive to heat and cannot survive above 70 °C, making thermal disinfection a dependable method. Unlike chemical disinfectants, it leaves no harmful residues on medical equipment, mitigating the risks associated with handling dangerous chemicals. This method also enhances compliance with infection control standards by effectively eliminating many types of bacteria, instilling confidence in its reliability.

Thermal disinfection involves using heat to remove contamination by exposing surfaces to specific temperatures for set durations. The pharmaceutical process of disinfecting, cooling, and filling vaccine vials is highly controlled and precise, prioritizing vaccine safety. The biggest risk in this process is contamination due to improper vial disinfection.

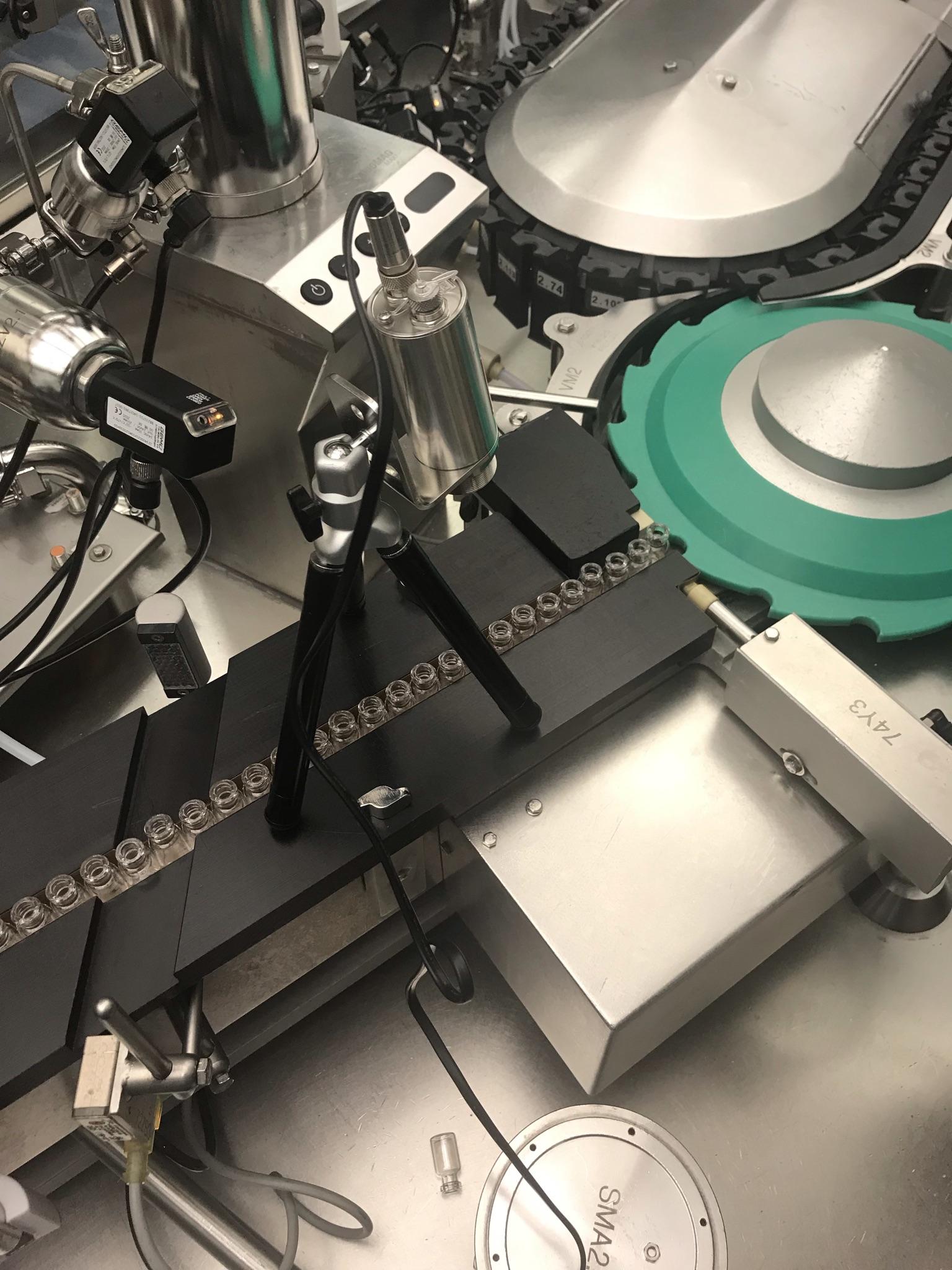

In this application, the temperature of each vial shall be checked throughout the thermal and chemical disinfection process. After cleaning and disinfecting in specialized machines, vials are transferred to a sterilizer, where the vials are dried at approximately 300 °C. Next, the vials pass through a cooling tunnel, bringing them to 25 °C in preparation for filling. An additional challenge in this application is the speed and number of vials requiring temperature checks. Vials often move quickly through the process, leaving only milliseconds to check temperatures, and temperatures constantly change throughout the process.

Conventional sensors are no option as they only monitor ambient temperatures. This principle may miss cold vial products as they only monitor the ambient temperature but not the temperature of the vials themselves. Non-contact infrared temperature sensors provide a solution by accurately measuring the true temperatures of pharmaceutical products without contamination risk. Due to their measurement principle, non-contact methods prevent impurities.

Streamlined Temperature Monitoring of Vials to Ensure Cleanliness with Stationary Infrared Cameras

Infrared monitoring the temperature of vials is a straightforward process. The emissivity of glass vials can be disregarded in this application due to the cavity effect. This phenomenon occurs when a small, enclosed space traps infrared radiation, causing it to bounce around and enhance heat detection. The cavity effect improves the accuracy and sensitivity of temperature measurements by increasing the apparent emissivity of the surfaces within the glass container. Low temperatures in this application require sensors with a long wavelength (8 µm to 14 µm). Optris’ portfolio includes the Xi camera series, featuring long-wave infrared cameras with a compact design for stationary installations.

The Optris Xi series thermal imaging cameras offer an ideal solution, particularly the Xi 80 and Xi 400 models. These OEM infrared cameras are easy to integrate into processes and can be mounted above the vial pathway, ensuring non-contact temperature measurement that eliminates contamination risks.

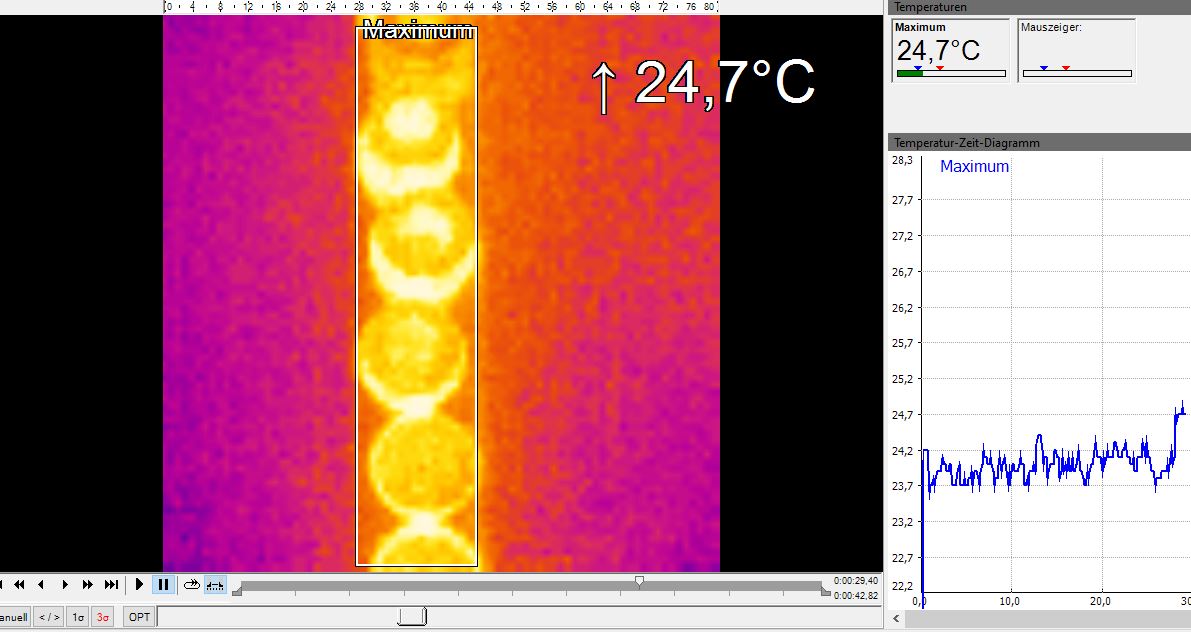

The Optris PIX Connect software sets up a measuring field to accurately monitor the temperature of vaccine vials at key points (immediately after the cooling tunnel and during separation before filling). This setup records the total number of vials and automatically detects any temperature anomalies with hotspot detection.

With a frequency of up to 80 Hz, Xi cameras can precisely record the temperatures of fast-moving vials in real-time. The temperature data is transmitted to a programmable logic controller (PLC) as 4-20 mA signals, enabling automated and regulated cooling. Vials with detected temperature issues can be easily identified and removed.

Optris Xi thermal cameras significantly reduce rejects and costs, optimizing the process.

Crucial Radiometric Property for Thermal Imagers for Accurate Temperatures in Pharmaceutical Manufacturing

Customers greatly benefit from the simple integration and extensive features of Optris infrared cameras and analysis software solutions. For a minimal investment, they receive a powerful, comprehensive package that addresses all challenges with minimal effort. The Xi cameras from Optris significantly optimize the production process of vaccine vials. The intrinsic feature of infrared temperature monitoring, measuring from a distance, ensures easy implementation. The various output functions allow easy integration into any process.

Features such as automatic hotspot detection and a frame rate of up to 80/27 Hz enable high-speed detection of critical temperatures, even with an extremely high number of objects passing through the measuring range for only a few milliseconds.

It is important to mention that a radiometric characteristic of such an infrared camera is essential for accurate temperature measurement. It provides precise temperature readings for each pixel, unlike standard infrared cameras, which only offer thermal visualization. This capability is crucial for processes like monitoring vaccine vials, where exact temperature control is vital to ensure product integrity. Radiometric cameras enable the detection of subtle temperature differences and anomalies. They also facilitate detailed analysis and documentation, essential for compliance with stringent regulatory medical standards in the pharmaceutical industry.

Recommended Products

Other Pharmaceutical & Medical Applications

Talk to us about your IR Temperature Measurement Requirements

There are over 300 different pyrometer variants to choose from in the Optris infrared pyrometer portfolio each optimized for material, spot size, distance from the target, and environmental conditions. Fortunately, there is a trained engineer to phone or chat with to guide you through the process of choosing the perfect infrared sensor for your application.

The same support is available for the extensive IR camera product line.