Comprehensive Temperature Profiling in Roto-Molded Kayak Production

Leveraging Cost-Effective Infrared Cameras for Multi-Area Temperature Profiling in Roto-Molded Plastic Part Production

Challenge

Inconsistent temperature distribution across complex roto-molded plastic parts hinders precise timing for inserting components, as single-spot sensors fail to capture the full thermal profile needed to ensure consistent quality during cooling and molding transitions.

Solution

An infrared camera captures comprehensive thermal images of the entire kayak hull, enabling precise identification of temperature zones and optimized timing for inserting accessories or releasing the part from the mold.

Benefits

- Enables precise timing for insertions based on actual part surface temperature

- Improves part quality by monitoring temperature across entire hull in real time

- Reduces waste and rework from improperly timed insertions or premature release

- Enhances process understanding and consistency through visual thermal feedback

- Lowers total system cost compared to multi-sensor single-point solutions

The Need for Comprehensive Temperature Profiling in Roto-Molded Plastic Part Production

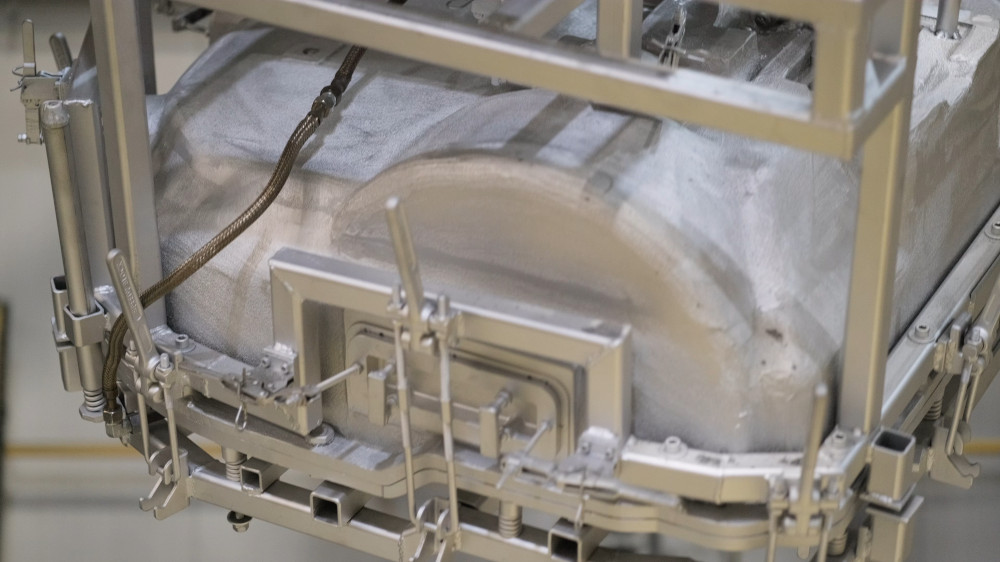

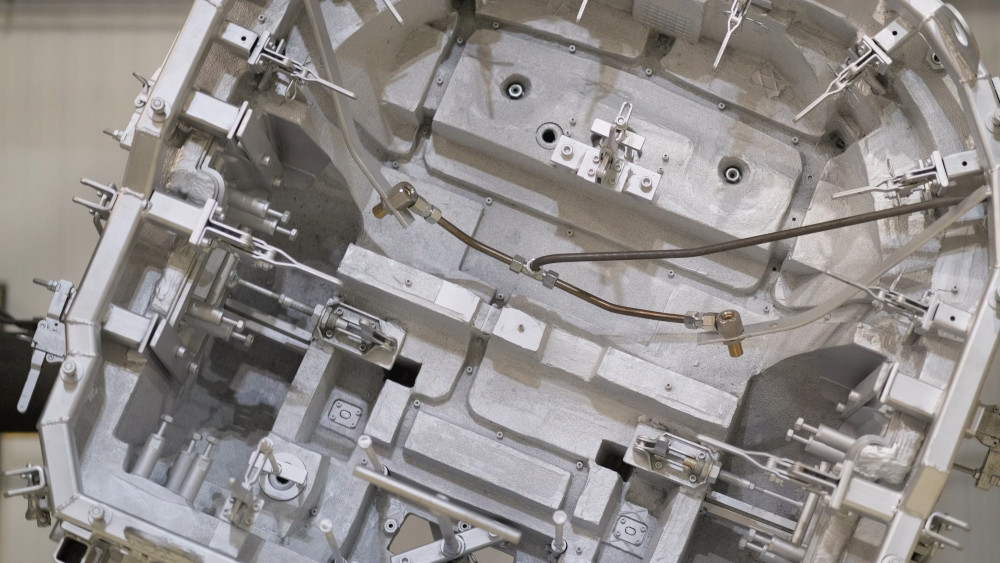

A kayak manufacturer uses a roto-molded linear polyethylene manufacturing process to produce kayaks with many plugs, anchors, and threaded devices used as attachment points for accessories. The timing of the insertion of these elements is critical, and the manufacturer has relied upon single-spot sensors to produce data used to time the addition of these elements. The roto-mold manufacturing process allows the manufacturer to vary the density of the plastic in important locations on the hull by holding the mold in certain positions for longer or shorter periods. This results in temperature variations when the hull is positioned in the cooling station because areas of increased density have higher thermal mass and retain temperatures from the molding process for longer periods. Single-spot sensors do not offer comprehensive temperature data informed by these variations in thermal mass. A temperature profile across the part is required.

A single Infrared Camera vs. multiple Pyrometers to improve Plastic Molding Quality Control

Hundreds of locations on the boat can be monitored with an infrared camera, and the cost of a mid-range resolution camera makes the camera a more affordable solution than numerous pyrometers, each targeted at a different area on the hull. The plastic hull is an ideal target for infrared temperature measurement because it has high emissivity in the low-temperature ranges (100 °C to 300 °C), which can be measured after the hull is released from the mold. A long wavelength detector response (8 µm – 14 μm) is ideal for these measurements. Areas on the target that are relatively small can be measured with small spot measurement tools in the PIX Connect software that collect temperature values from just a few pixels. Ellipse or polygon tools can be deployed for average temperatures of an area on the vessel, yielding critical temperature data. Initially, the thermal images and real-time temperature information displayed for each area can be used in manual mode to determine the ideal timing for release from the mold or the addition of small inserts (drain plugs at 85 °C), larger inserts (80 °C), sub-molds, and rod holders (75 °C).

The frame-grabbing feature in PIX Connect software can trigger storage from an external input (e.g., photo-eye) at a precise time, allowing the software to store thermal images and temperature data at a precise moment after release from the mold. Alternatively, temperature data can be sent directly to a programmable logic controller (PLC) for data logging or control of manufacturing processes.

Affordable high quality thermal imaging made for process control applications

Many manufacturers cannot properly address their temperature-related quality control requirements with single-spot sensors but do not consider an infrared camera because they perceive it to be cost-prohibitive. This predisposition is well-founded given the historical cost of infrared cameras and the prices still quoted today for fully radiometric thermal imaging by many suppliers. The Optris Xi 400 leverages decreasing costs for infrared detectors and a design focused on affordability to address customers with large multi-area measurement requirements. The license-free Optris PIX Connect software makes the solution even more affordable. It was designed to support multiple-point temperature data collection and communicate that information in data formats easy to integrate with customer data recording devices and controllers. Most importantly, it reduces costs by eliminating the need to develop custom software to address a multiple-point temperature data collection process. Simple area and point measurement tools were easy to locate on the display, and simple interface commands made it easy to send the information to the customer PLC.

Competent support from Optris Application Engineers, who guided the customer through the right camera and optics selection and also devised the most effective measurement tool deployment strategy, eliminated concerns that the implementation on the production line would not be successful.

Recommended Products

Other Plastic Applications

Talk to us about your IR Temperature Measurement Requirements

There are over 300 different pyrometer variants to choose from in the Optris infrared pyrometer portfolio each optimized for material, spot size, distance from the target, and environmental conditions. Fortunately, there is a trained engineer to phone or chat with to guide you through the process of choosing the perfect infrared sensor for your application.

The same support is available for the extensive IR camera product line.