Thermal Imaging for Optimizing the Plastic Welding Process in Water Filter Manufacturing

Mitigating Plastic Joint Leakages with Precision Infrared Temperature Control

Challenge

The manufacturer needs accurate, rapid temperature measurements during the fast heating process of plastic parts to ensure precise welding and prevent leaks. Temperature deviations must be detected to avoid production of defective filters.

Solution

An infrared camera provides real-time temperature monitoring, allowing rapid detection of temperature deviations. It ensures precise welding and automates reject sorting by seamlessly integrating with the production process.

Benefits

- Automated temperature control enhances welding precision and minimizes the risk of leaks.

- Real-time temperature data allows immediate reaction to deviations, improving quality assurance.

- Reliable rejection of defective filters streamlines the production process.

- Integration into the control system enables effortless process automation.

- Compact, cost-effective solution maximizes production efficiency without significant investment.

Leakages of Plastic Joints due to incorrect Temperatures

A manufacturer requests a solution to monitor the heating and welding process of producing water filters. These filters comprise several plastic components that are welded together by heating and melting their edges using infrared emitters.

The manufacturer needs a reliable temperature measurement system that can accurately measure temperatures rapidly and automatically regulate the heating process in case of deviations. Additionally, it is crucial to detect any possible rejects accurately.

The manufacturing process for water filters is divided into several steps. Initially, raw materials, typically thermoplastics such as polypropylene (PP) or polyethylene (PE), are melted and molded into the desired shapes. These parts include the filter housing, filter elements, and connections. Once shaped and cooled, these plastic parts must be joined to create a seamless, watertight connection.

Infrared heaters heat the contact surfaces of the plastic parts to be joined. This contactless heating minimizes the risk of contamination and ensures uniform heating. The infrared emitters, quartz glass tubes with tungsten or carbon filaments, generate infrared radiation in the mid-infrared range (2 µm to 6 µm), which is well absorbed by the plastic. To achieve optimal melting and bonding, the weld seam must be heated precisely to 150 °C.

The manufacturer also requires a fast temperature measurement method, as the heating process occurs quickly and lasts just a few seconds. Incorrect heating will lead to leaks, so temperature monitoring is essential.

Automating Plastic Welding Precision through Thermal Visualization and Infrared Temperature Measurements

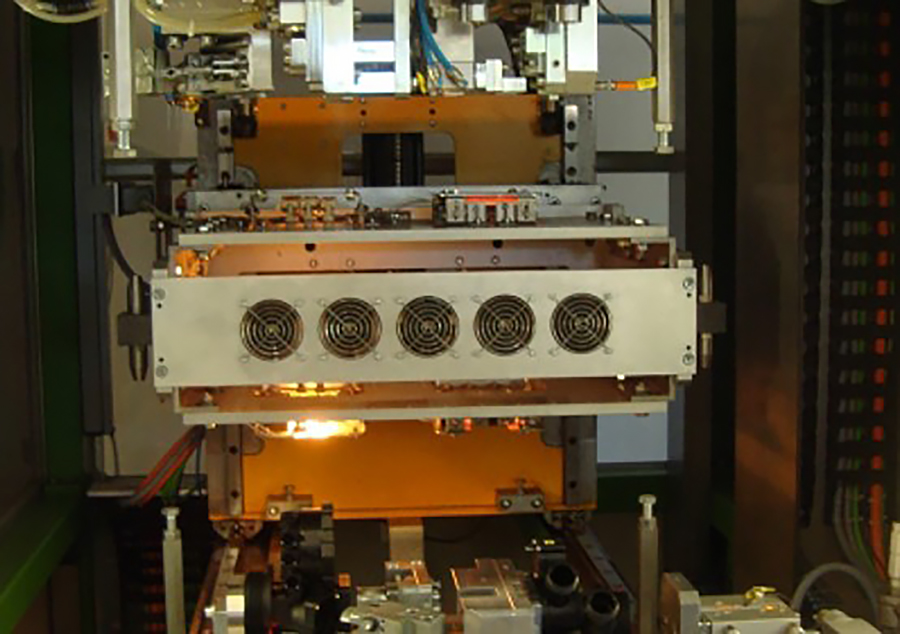

To address this issue, the manufacturer employs the compact Spotfinder industrial camera Xi 400 from Optris. This infrared thermal imaging camera is ideally suited for OEM applications. The Xi 400 infrared camera fulfills the customer’s primary needs: reliable temperature recording in the welding areas, rapid temperature measurement, and seamless integration into the process, enabling automation.

The Xi 400 IR camera measures temperature distribution with high optical resolution (382 x 288 pixels) and continuously monitors the heating of the weld seam in real-time. Its frame rate (80 Hz / 27 Hz) facilitates rapid temperature measurement, which is critical since the heating tools open for only a short duration.

Two Xi 400 infrared cameras—one for the upper mold and one for the lower mold—are installed on multiple systems. The motor focus integrated with the infrared imager ensures precise recording of the areas.

The PLC queries data analogously, and a good/bad signal is output. This allows immediate reaction to temperature deviations and ensures that only correctly welded water filters are processed further.

Precise control of the heating process enables the identification and sorting of rejects. This process is fully automated, with the camera integrated into the production line via a process interface that ensures a simple connection to the plant’s control systems.

Improving Plastic Welding Processes with Affordable Optris Infrared Cameras

The fast measurement process and high accuracy of the Xi 400 contribute significantly to efficiency and quality assurance for manufacturers.

Manufacturers benefit greatly from the simple integration and extensive functions of the Optris infrared cameras and analysis software solutions.

For a minimal investment, manufacturers receive a powerful complete package that addresses all challenges with minimal effort. For example, the Xi cameras from Optris significantly optimize the production process of water filters and plastic welding processes in general.

Features such as automatic hotspot detection and a frame rate of up to 80/27 Hz enable critical temperatures to be captured quickly, even for large or complex measuring surfaces that only appear in the measuring range for a few milliseconds.

The Xi 400’s high optical resolution, with 382 x 288 pixels and a spot-to-distance ratio of up to 390:1, makes it possible to precisely detect even the smallest temperature differences. The Xi cameras also offer a high thermal sensitivity (NETD) of 50 mK, enabling particularly precise temperature measurements. With a wide temperature range from -20 °C to 900 °C, they are versatile and can cover different process requirements.

The robust and compact imager with motorized focus ensures the camera works reliably even under difficult conditions.

Thanks to flexible connection options, such as the industrial process interface (PIF), the cameras can be easily integrated into control systems. The recorded temperature data can be fed into a PLC at 4-20mA, enabling efficient automation of the process.

Recommended Products

Other Plastic Applications

Talk to us about your IR Temperature Measurement Requirements

There are over 300 different pyrometer variants to choose from in the Optris infrared pyrometer portfolio each optimized for material, spot size, distance from the target, and environmental conditions. Fortunately, there is a trained engineer to phone or chat with to guide you through the process of choosing the perfect infrared sensor for your application.

The same support is available for the extensive IR camera product line.