Dual Color Infrared Pyrometer for Physical Vapor Deposition Process

How Advanced Infrared Pyrometry Enhances Sputtering Physical Vapor Deposition Processes for Optimal Thin Film Coatings

Challenge

Precise temperature control is essential in PVD to ensure coating uniformity, minimize defects, and maintain film properties, yet fluctuating emissivity and extreme temperatures complicate accurate measurement and process stability.

Solution

Ratio infrared sensors are integrated into the PVD system to provide consistent, emissivity-independent temperature data, enabling precise closed-loop control even under high electromagnetic interference and extreme temperatures.

Benefits

- Ensures consistent thin film quality by maintaining precise deposition temperature

- Reduces production defects through stable and repeatable thermal control

- Enables closed-loop process optimization using reliable real-time temperature data

- Minimizes downtime and increases throughput with fast, accurate temperature feedback

- Supports long-term process stability even under extreme thermal and electromagnetic conditions

The Crucial Role of Temperature in Physical Vapor Deposition Process

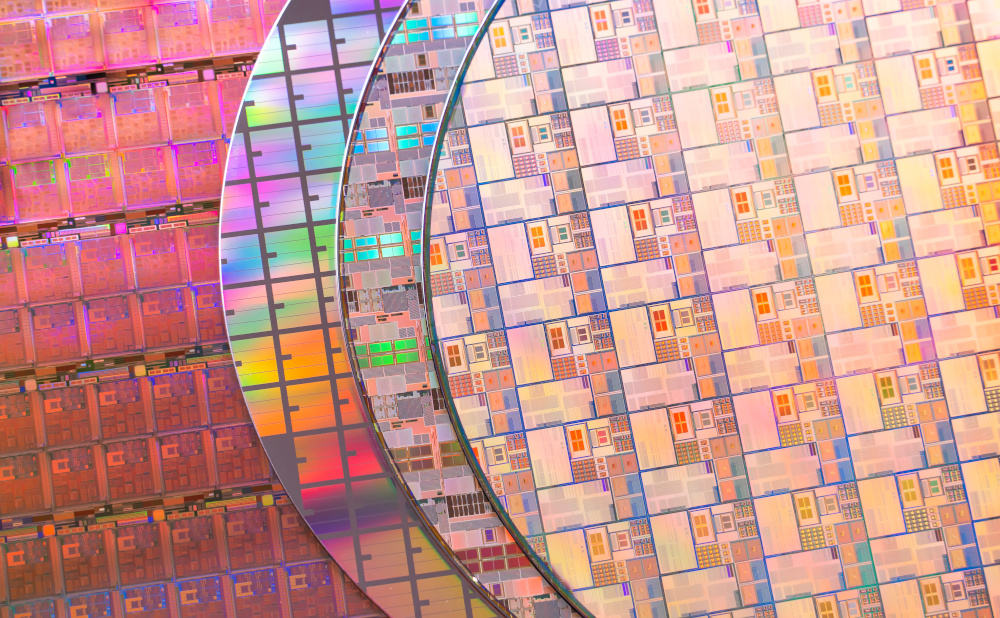

Physical vapor deposition (PVD), or physical vapor transport (PVT), involves vacuum deposition methods to produce thin films and coatings on substrates such as metals, ceramics, glass, and polymers. This technique is essential in manufacturing thin films for optical, mechanical, electrical, or chemical functions, particularly in semiconductors like photodiodes and filters. PVD involves the transition of material from a condensed phase to a vapor phase and then back to a thin film condensed phase, with sputtering and evaporation being the most common PVD processes.

Thermal evaporation is a process in which a coating material is vaporized, transforming it into a gas, enters a reaction chamber, and condenses onto the surface of a substrate material at relatively low process temperatures. A sputtering PVD process begins by placing the coating materials on a magnetron in a solid form called a target. Maintaining a clean environment with only the selected materials at high temperatures is crucial for achieving highly pure coatings. This is done by evacuating the chamber to remove almost all molecules and then backfilling it with a process gas, such as argon, oxygen, or nitrogen, chosen based on the material to be deposited.

Once the conditions, such as temperature and pressure, are set, the PVD coating process commences by applying a negative electrical potential to the target material. The chamber body serves as the positive anode or ground in this process. This electrical potential propels free electrons away from the magnetron, leading them to collide with process gas atoms and strip them of electrons, thereby creating positively charged process gas ions. These ions are then accelerated toward the magnetron, carrying enough energy to ‘knock off’ or ‘sputter’ some target material. This sputtered material accumulates on surfaces in the magnetron’s path, eventually depositing onto the final substrate.

The plasma glow, a visible indicator during the process, results from ions recombining with free electrons into a lower energy state, releasing excess energy as light. This glow serves as a visual cue, aiding in the monitoring of the thin film deposition, which continues at a constant rate until the desired thickness is achieved. At this point, the power is removed from the cathode, marking the completion of the process.

The process temperature is critical in a PVD process because it directly influences the quality and characteristics of the deposited thin film. Temperature affects the material vaporization rate, the vaporized particles’ energy, and their mobility on the substrate surface, which in turn impacts the film’s adhesion, density, and crystallinity. Precise temperature control ensures uniform deposition, minimizes defects and allows for the desired mechanical, electrical, and optical properties of the coating. Moreover, maintaining an optimal temperature prevents damage to the substrate and ensures the consistency and repeatability of the PVD process. Certified and traceable profile information documentation is also necessary for regulatory industry compliance.

Integrating Optris Infrared Pyrometers in PVD Machinery

To ensure repeatable process control in PVD machinery, a manufacturer specializing in high-volume production has integrated multiple ratio infrared sensors from Optris into their PVD sputtering machinery for silicon carbide (SiC) crystal growth and annealing. An RF induction heating coil is utilized in this PVD process, which involves polycrystalline silicon carbide sublimation at high temperatures up to 2500 °C. This coil operates in the kilohertz range, providing the necessary inductive heating.

The two-color principle of infrared thermometry is employed for the best precision in temperature accuracy, a wide temperature range, and high repeatability under changing emissivity. Unlike single-wavelength pyrometers that measure temperature based on the absolute intensity at one wavelength, two-color pyrometers calculate temperature by comparing the intensity of radiation emitted at two different wavelengths from a surface. This ratio-based measurement, with its precision, is less affected by changes in emissivity, ensuring more reliable readings over varying temperatures and compensating for emissivity variations.

The Optris CTratio series ratio pyrometers stand out for their accuracy. The fiber-optic CTratio features a tiny sensing head size that can sustain high operating temperatures up to 315 °C, a laser, and measures temperatures from 250 °C to 3000 °C. The rugged, electrically isolated sensing head and fiber optic cable make the CTratio insensitive to electromagnetic fields. The two color pyrometers have been integrated directly with digital RS485 interfaces to resolve the smallest temperature information and feed it into the PID controller.

The finalized PVD system includes robust process controls to ensure temperature and pressure stability throughout extended deposition runs, facilitating the reliable production of low-defect SiC boules. The infrared temperature data is the input for a PID control system, which maintains temperature within half a degree to ensure process consistency and quality.

Unmatched Value and Support from Optris Makes the Difference

In this application, the Optris pyrometer has proven to be a highly reliable and cost-effective solution for temperature measurement in a PVD process. Delivering accurate and consistent temperature data at just a third of the price of competing products, the Optris pyrometer stands out as an economical choice without compromising sensor performance. Additionally, the lead time for the infrared sensor has been significantly shorter, allowing for faster implementation and development iterations.

Optris’s commitment to customer satisfaction is more than providing high-quality products. Their dedication to excellent customer service and technical support is evident through their proactive approach. Qualified engineers from Optris have visited and tested the application with the customer multiple times, ensuring that the pyrometers are optimally configured and performing to the highest standards. This hands-on support has been crucial in addressing any challenges and ensuring the successful integration of the pyrometers into the customer’s PVD process.

Moreover, Optris’s ongoing technical support ensures that any issues are promptly addressed, and customers can rely on their expertise for continuous process optimization. This comprehensive approach not only guarantees immediate success but also fosters long-term partnerships.

Recommended Products

Other Semiconductors Applications

Talk to us about your IR Temperature Measurement Requirements

There are over 300 different pyrometer variants to choose from in the Optris infrared pyrometer portfolio each optimized for material, spot size, distance from the target, and environmental conditions. Fortunately, there is a trained engineer to phone or chat with to guide you through the process of choosing the perfect infrared sensor for your application.

The same support is available for the extensive IR camera product line.