Durable, Economical, and Reliable Infrared Temperature Measurement Solutions for Polysilicon Growth Processes

Ensuring High-Quality Polysilicon Production with Precise Thermal Management in a Polysilicon Siemens Process

Challenge

Maintaining precise and uniform rod temperatures during polysilicon deposition is difficult due to high temperatures, varying emissivity of silicon, and inaccessibility for contact sensors in the harsh reactor environment.

Solution

Infrared pyrometers using fiber optics and ratio technology enable accurate, non-contact temperature measurement in confined, high-temperature areas, ensuring consistent control during the critical CVD stage of the Siemens process.

Benefits

- Ensures uniform polysilicon deposition, reducing structural defects and improving purity

- Prevents rod overheating and potential reactor failure through accurate temperature control

- Operates reliably in extreme heat and chemically aggressive environments

- Enables precise monitoring in confined reactor spaces without process interference

- Supports faster integration and process optimization with robust technical support

The Critical Role of Temperature Control in the Siemens Process for Silicon

Pure polysilicon is the most common material for manufacturing integrated circuits and solar cells. Polysilicon is produced and based on a chemical vapor deposition process in the so-called Siemens process. Despite being relatively expensive and slow, its ability to produce high-quality polysilicon remains the dominant method globally, with about 75% of the world’s polysilicon production relying on this technology due to its ability to produce highly pure polysilicon. Cost reductions, mainly driven by low-cost plants in China, have made this process more economically viable.

The Siemens process starts with metallurgical-grade silicon, which contains about 0.5% to 1.5% impurities. To purify this silicon, it is ground into small particles and reacted with hydrogen chloride to produce trichlorosilane (TCS), a highly volatile liquid. With its low boiling point of 31.8 °C, the TCS is then purified through distillation. The purified TCS is introduced into a chemical vapor deposition reactor in the next step. This reactor’s thin silicon filaments are electrically heated to temperatures up to 1150 °C. The TCS decomposes, depositing silicon onto these filaments and forming polysilicon rods with 150mm to 200mm diameters. This step is highly energy-intensive and critical to achieving the necessary purity.

Temperature control is vital throughout the Siemens process, particularly during the CVD stage. The silicon rods must maintain a consistent temperature as they grow, which requires careful power adjustment to avoid overheating and potential melting of the rods. The consistency of the temperature ensures that the deposition of silicon from the TCS onto the silicon filaments occurs uniformly, preventing defects in the polysilicon structure. It is also essential to avoid overheating, which could cause the rods to melt and disrupt the entire process.

Due to the nature of the crystal growth process, monitoring the silicone rod’s temperature with conventional contact temperature sensors is not possible. Infrared temperature monitoring is the only option to control this time-consuming, energy-intensive, and expensive process.

Achieving Reliable Silicon Temperature Readings with Infrared Pyrometers in the Siemens Process

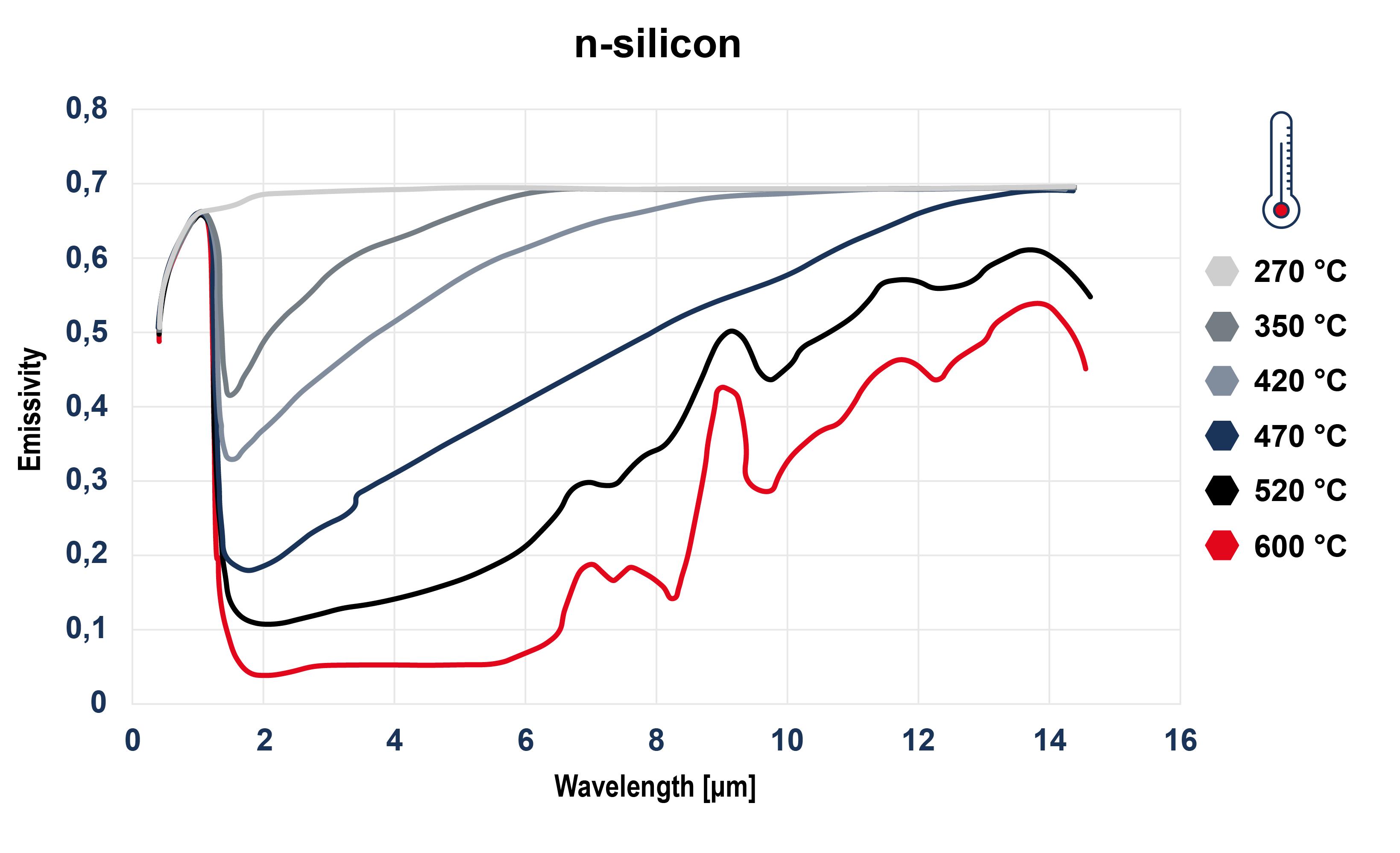

Silicon’s emissivity varies with temperature, wavelength, and surface characteristics, resulting in complex and dynamic behavior across different spectral ranges. To reliably measure silicon temperature, it is advised to use a short infrared wavelength around 1 µm, where the emissivity remains stable despite temperature changes. Two-color pyrometers can be advantageous because they do not require filling the entire sighting field to measure rod temperature. They can be used with explosion-proof housing when hydrogen gas is present.

The fiber optic CTratio two-color pyrometer is effective for measuring the temperature of the substrate or the deposited polysilicon film. These two-piece pyrometers are compact and equipped with flexible optical fibers, allowing them to be positioned in confined or hard-to-reach areas. They are designed to withstand harsh operating conditions, including high ambient temperatures, vibrations, and chemical exposure. Ratio technology provides accurate temperature measurements by comparing the intensities of two different wavelengths of light, reducing errors caused by factors such as emissivity variations, optical interferences, or damping in the optical path.

Still, some facilities prefer to use single-color pyrometers, which measure at a single wavelength and can be affected by emissivity changes. They are looking for repeatability in the Siemens process rather than accurate temperature. However, in a two-color unit, the smart ratio mode can teach the pyrometer these emissivity or ratio changes, ensuring accurate measurements even when emissivity at the two wavelengths does not change uniformly.

Durable, Economical, and Reliable Infrared Temperature Measurement Solutions for Polysilicon Growth Processes

The fiber-optic CTratio with a passive sensing head is highly advantageous for installation in challenging environments. This technology keeps the electronics away from the harmful operating conditions of the reactor, ensuring durability and longevity. The non-contact measurement system prevents interference with the process, eliminating contamination risk. Given the extremely high temperatures and potentially hazardous surrounding atmosphere, fiber-optic technology proves essential for maintaining accurate and safe temperature measurements.

The Optris pyrometer is not only reliable but also highly cost-effective. It delivers accurate and consistent temperature data at half the price of competing products, making it an economical choice without compromising sensor performance. The significantly shorter lead time for the infrared sensor also allows for faster implementation and development iterations.

Moreover, Optris’s ongoing technical support ensures that issues are promptly addressed, allowing customers to rely on their expertise for continuous process optimization. This comprehensive approach not only guarantees immediate success but also fosters long-term partnerships.

Recommended Products

Other Semiconductors Applications

Talk to us about your IR Temperature Measurement Requirements

There are over 300 different pyrometer variants to choose from in the Optris infrared pyrometer portfolio each optimized for material, spot size, distance from the target, and environmental conditions. Fortunately, there is a trained engineer to phone or chat with to guide you through the process of choosing the perfect infrared sensor for your application.

The same support is available for the extensive IR camera product line.