Infrared Scanner System

The infrared scanner system is a specialized device used for non-contact temperature measurement across a wide area. It captures temperature data along a single line and, using either a rotating mirror or other mechanical scanning mechanisms, sweeps this line across the area of interest, creating a two-dimensional temperature map line by line. Infrared scanners are known for their high-speed scanning capabilities, making them suitable for monitoring fast-moving processes or objects.

In manufacturing, infrared scanners are used to monitor and control temperatures in processes such as steel and glass production, and paper and plastic manufacturing. They are also employed in inspecting materials on conveyor belts, monitoring the temperature distribution of kilns and furnaces, and inspecting automotive components during production.

Traditional infrared scanner systems, despite their utility in various industrial applications, have several disadvantages. One significant drawback is their reliance on mechanical components for scanning. The rotating mirrors or other mechanical parts can wear out over time, leading to maintenance issues and potential downtime. This mechanical complexity also adds to the overall cost and size of the device, making it less compact and more expensive compared to other infrared imaging technologies. Traditional scanners also typically have a narrower field of view compared to modern infrared cameras, meaning they need to be positioned more precisely and may require more complex setups to cover the same area that a wide-angle infrared camera could capture in a single frame. Additionally, the resolution along the scanning line is generally higher than across the scanning direction, which can lead to uneven detail in the resulting thermal image.

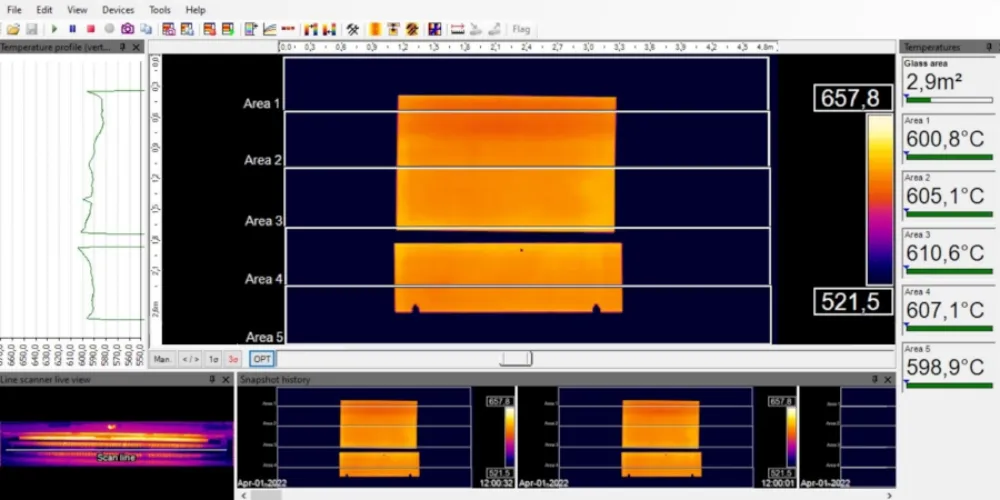

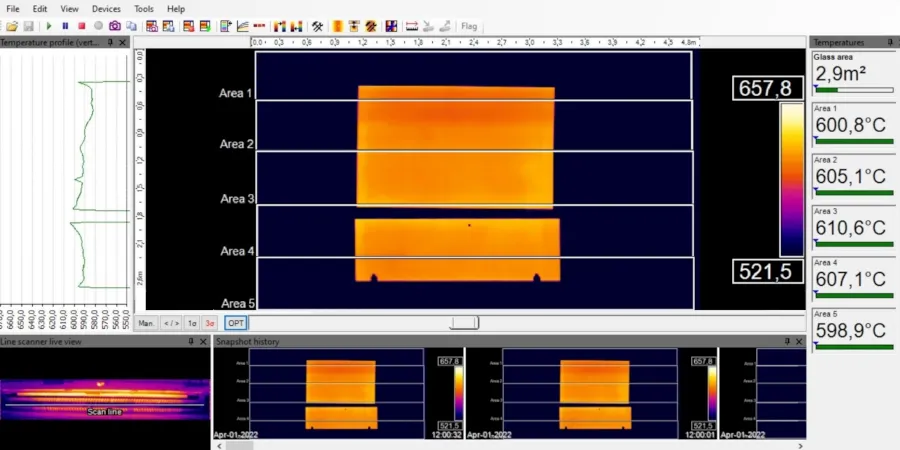

Infrared scanners based on infrared cameras are a sophisticated alternative, providing the same functionality with fewer challenges and at a lower cost. Software algorithms map a diagonal line across the focal plane array, sample the temperature data at each frame, and map it into a new image. This software simplifies the commissioning and alignment of the IR cameras, as the line does not need to be straight. Additionally, IR camera-based scanners cover large areas efficiently with less image distortion than traditional scanners and provide better image resolution. Infrared cameras feature robust construction with fewer mechanical components, lowering maintenance needs and increasing longevity. Their more compact size allows for easy installation and integration into various industrial settings.

Back to LexiconRecommended Products

Talk to us about your IR Temperature Measurement Requirements

Our Infrared Temperature Measurement experts can help you find the right Optris product for your application.