IR Microscopes

Innovations in Infrared Microscopy for Industry and R&D

Explore the innovative non-contact temperature measurement with Optris IR Microscopes, featuring the Xi 400, PI 450i and PI 640i models (optionally with MO2X microscope optics). These high-precision thermal imagers deliver up to 2X magnification, achieving unparalleled detail and accuracy with superior resolution and sensitivity. Ideal for applications in material science, electronics manufacturing, and research and development, these microscopes are specifically designed to provide in-depth thermal analysis and diagnostics. With the ability to detect features as small as 8 µm, they offer insights far beyond the capabilities of standard optical microscopes.

These advanced IR Microscopes are essential for professionals who require detailed examination of thermal properties to innovate and enhance product quality. The enhanced imaging capabilities facilitate a comprehensive understanding of heat distribution and properties at the microscopic level, crucial for developing more efficient and reliable materials and components. Whether you’re improving existing products or pioneering new technologies, Optris IR Microscopes provide the critical data needed for success in today’s competitive industries.

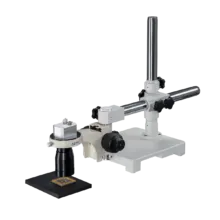

Optris IR Microscopes

Click here to find the product that suits your demands.

Why Optris IR Microscopes?

- Crisp thermal imaging of small components down to 80 µm (Xi 400), 28 µm (PI 640i MO) or 8 µm (PI 640i MO2X)

- Fully radiometric real time recording of thermal sequences with full measurement analysis available on every single frame on playback with license free PIX Connect software

- Time vs. temperature data logging on any pixel in the scene stored in CSV files for temperature trending on transient events

- Hands-free operation

The ever-increasing integration density in new electronic designs means that the amount of heat resulting from power loss is constantly increasing. Another factor driving the need for infrared microscope optics is continual miniaturization, which can impede efficient heat dissipation. Even applications which carry relatively large currents are becoming more and more common – in drive technology for example – thanks to the use of power electronics.

The lifespan of semiconductor elements is hugely dependent on temperature. and increase in temperature of 10 °C will cause a 50% reduction in lifespan. This means that developers of electronic assemblies are faced with the challenge of allowing for the thermal behavior of circuit boards and assemblies. The temperatures of semiconductors, printed circuit boards or entire assemblies are best measured with the help of infrared technology. The measuring procedure is quick, precise and non-contact – a consideration of particular importance in electronics manufacturing. When measuring, checks should be made to see where exactly a circuit board is showing temperature variations. Care should also be taken to make sure that measurements are made on high emissivity surfaces (Teflon, Polyimide, fiberglass and ceramics) and not metal surfaces which reflect infrared energy.

The causes for excessive temperatures can be manifold: defective components, incorrectly dimensioned circuit paths or poorly soldered joints. To properly record the temperatures of very small components and structures on a circuit board, and infrared camera with suitably high resolution and microscope optics designed to focus that resolution on small targets are necessary. With the right camera-optic combination, you can clearly identify which component on a printed circuit board is at a temperature beyond its operating specification.

Of equal importance is understanding when the camera is fully resolving a small component. Just because you can clearly see on the thermal image at the point where lead connects with and integrated circuit does not mean you can measure the temperature accurately. The infrared industry has turned to specifying pixel size to present the resolving power of the IR camera-microscope combination. However, a single pixel will not respond fully to the radiant heat emitted from a surface the size of a single pixel resulting in a lower temperature measurement. Typically, a 3 x 3 cell matrix of pixels on the target is necessary to report and accurate temperature measurement in line with the accuracy specification for the camera. If the temperature is important, and it frequently is when assessing and electronic component, do not rely on pixel size. Measurement Field of View (MFOV) is the performance parameter that defines the size of target that can be measured accurately.

Infrared cameras have typically been used in design validation, but research is underway to incorporate Optris infrared cameras into the production phase during the reflow process to validate temperature on the board and its components as it proceeds through the oven. Optris PIX connect software is used in line scan mode to gather temperature data on a single line through a small slit opening in the oven. The software converts the temperature data from the single line to produce a full thermal image of the board using the movement of the board through the camera field of view to recreate the vertical dimension. This research and other research efforts will expand the use of infrared camera technology in the electronics arena.

IR Microscope Products Are Suitable For

Talk to us about your IR Temperature Measurement Requirements

Our Infrared Temperature Measurement experts can help you find the right Optris product for your application.