Infrared Thermometers & Pyrometers

Affordable industrial infrared sensors for precise temperature measurement

Our Solution for Your Requirements

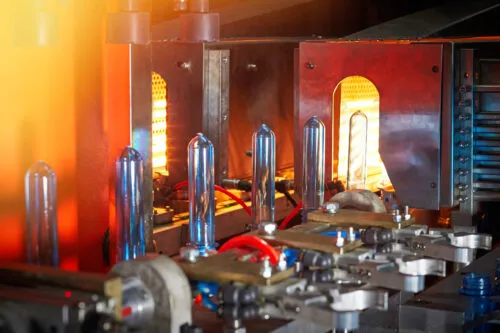

Optris infrared thermometers and pyrometers for remote spot measurements are particularly well suited for precise temperature monitoring of industrial manufacturing processes, research and development, and function checks of a diverse range of devices and systems.

In over 20 years of designing a building infrared pyrometers, we have evolved and unmatched variety of sizes, temperature ranges, spectral responses, and accessories to address virtually any customer requirement. The product line begins with simple and affordable sensors and extends to industrially hardened sensors that make use of the ratio technique to improve the accuracy of metal targets in environments where dust, dirt, or other elements attenuate the infrared signal.

The product line includes a full array of spectral response options ideally suited for measuring a wide variety of materials including metals, plastics, glass and a variety of other materials. The line includes special sensors that survive very hot environments, high speed sensors, sensors that measure very small targets and sensors that include integral cameras for target viewing. Virtually any remote infrared temperature measurement application can be addressed by the Optris pyrometer product line.

CS Series

Compact single-piece industrial infrared pyrometer

Starting at 95 € the CS LT marks the entry level for industrial infrared pyrometry. The wide measurement range of -50 °C to 1030 °C, combined with a temperature resolution of 50 mK and a very compact stainless steel housing makes this sensor ideal for OEM use and installations in machinery where small size matters. The CS LT provides analog and alarm outputs, an intelligent LED indicator and an USB interface for easy setup and integration.

CS Series

CSmicro series

Single-piece micro-sized industrial infrared pyrometers

Optris introduces new benchmarks in sensor head size and durability for industrial pyrometers. The miniaturized CS micro sensing heads typically measure 14mm (w) x 28mm (length) making them perfect for use in small and cramped mounting locations. The small size and affordable pricing of the infrared sensors from the Compact Series are often used as components in other equipment that require require temperature information to perform properly.

CSmicro seriesCT Series

Affordable robust industrial pyrometers for applications with high surrounding temperatures

The two piece pyrometers of CT series consist of a sensing head and a separate electronic box. This variant offers a straightforward device setup and shows temperature readings on a smart LED, but also provides sensor control and additional outputs through the electronics box. This includes the ability to select from various interfaces like USB, RS232, RS485, Modbus RTU, Profibus DP, and Ethernet.

CT Series

CSlaser Series

Innovative IR thermometers with double laser sighting and various optics

The CSlaser High Performance Series pyrometers are ideal for harsh industrial environments. Designed with robust cooling or air purging accessories, they ensure sensor protection in tough conditions. The CSlaser features a one-piece unit that incorporates diverging lasers, simplifying setup by clearly illuminating the precise size and location of the measurement spot.

CSlaser SeriesCTlaser Series

Innovative IR thermometers with double laser sighting and various optics

The CTlaser High Performance Series pyrometers are perfect for demanding industrial settings. Equipped with robust cooling or air purging accessories, they provide essential protection for the sensor. The CTlaser separates the sensor head from a remotely positioned electronics box, which includes an LED display and user controls. Diverging lasers are also included, making it easy to pinpoint the exact size and location of the measurement spot.

CTlaser Series

CSvideo Series

Video pyrometers with laser aiming for precise temperature measurement in areas with limited access

The sensor alignment of our CSvideo devices is made easier by the integrated video sighting and cross laser aiming features. Additionally, the sensor housing of the CSvideo head is constructed of stainless steel (rated IP65/NEMA-4).

CSvideo SeriesCTvideo Series

Video pyrometers with laser aiming for precise temperature measurement in areas with limited access

The CTvideo head’s sensor housing is crafted from stainless steel with and equal rating, while the sensor electronics are located in a separate die-cast zinc box. CTvideo includes an on-board camera that supplies a real time video image of the target and and overlay displaying the precise location of the laser illuminated measurement spot which are both visible on the Compact Connect software or the IR Mobile app.

CTvideo Series

CTratio series

Fiber Optic (Ratio) Pyrometers for Extremely High Temperatures

Optris CTratio pyrometers use infrared energy measured with two wavelengths to improve measurement accuracy of high temperature metal surfaces when dust in the optical path or dirt accumulation on IR windows partially attenuates the infrared signal. The fiber-optic sensing head withstands temperatures of 200 °C and increases options for mounting of the separate configurable electronics box with cable length options up to 15 meters.

CTratio seriesCSvision Series

Innovative Ratio Pyrometers and High Quality Video Alignment

The CSvision Series combines a visible camera and laser sighting with a ratio sensor capable of measuring high temperature metal targets (up to 3500 °C) through dusty environments. The on board camera and and innovative two-step brightness reduction filter (BRF) provides perfect imagery even on extremely and and bright objects. The motorized focus supports measurement from a variety of mounting locations.

CSvision Series

Accessories for Infrared Thermometers & Pyrometers

Enhance your IR thermometers with Optris’ accessories for optimal performance and extended functionality

A remote infrared sensor must endure harsh industrial conditions, delivering accurate measurements even in high heat or dusty air. Cooling and air purging accessories help maintain performance. Versatile mounting options, including adjustable brackets, furnace wall mounts, and sighting tubes, ensure proper positioning and minimize environmental interference, protecting the sensor’s optical path for reliable and precise temperature measurement.

Accessories for Infrared Thermometers & PyrometersWhich Is the Right Infrared Thermometer?

Click here to find the product that suits your demands.

Talk to us about your IR Temperature Measurement Requirements

Our Infrared Temperature Measurement experts can help you find the right Optris product for your application.

Optris introduces new benchmarks in sensor head size and durability for industrial pyrometers. The miniaturized CS micro sensing heads typically measure 14mm (w) x 28mm (length) making them perfect for use in small and cramped mounting locations. The small size and affordable pricing of the infrared sensors from the Compact Series are often used as components in other equipment that require require temperature information to perform properly.

Unlock the Potential of Precision with Optris IR Thermometers and Pyrometers

In the realm of industrial measurement technology, Optris has established itself as a leader, offering innovative infrared (IR) thermometers and pyrometers that are pivotal for precision temperature monitoring. Optris’ IR thermometers and pyrometers provide reliable and accurate temperature readings essential for quality control, safety, and operational efficiency.

Optris IR Thermometers: Precision at a Distance

Optris IR thermometers allow users to measure surface temperatures from a distance, ensuring safety especially when dealing with extremely high temperatures or hazardous substances. Suitable for a variety of applications, Optris IR pyrometers are indispensable tools in industries such as metallurgy, glass production, and plastics engineering.

Each thermometer is designed with state-of-the-art optics and advanced sensor technology to deliver precise readings. With a wide range of product lines and models available, Optris ensures that whether you need to measure the temperature of a tiny component or a large furnace, there is and IR thermometer tailored to your needs. Additional accessories make these infrared sensors versatile and durable for harsh industrial environments.

Optris Pyrometers: Harnessing Accuracy in High Temperatures

Optris pyrometers are specialized for high-temperature applications where traditional thermometers might fail. These devices are critical in processes that require the highest level of accuracy and reliability. Pyrometers from Optris are ideal for metal forging, semiconductor manufacturing, and thermal processing of materials, where precise temperature control is crucial for product quality.

The pyrometers feature single-color and dual-color options, allowing for flexibility in dealing with different types of materials and surfaces. The dual-color models are particularly effective in cases where the target’s emissivity is unknown or changes with temperature, providing consistent and reliable readings. Enhanced with digital interfaces and configurable I/O options, Optris pyrometers can be easily integrated into existing control systems, facilitating real-time monitoring and adjustments.

Integration and Software Solutions

Understanding that data plays a critical role in modern industrial operations, Optris equips its IR thermometers with powerful software solutions. These tools not only facilitate the visualization and analysis of temperature data but also enhance the ability to archive and retrieve data for compliance and quality assurance purposes.

Why Choose Optris?

Accuracy and Reliability: Optris’ products are rigorously tested and calibrated to ensure they deliver accurate and consistent results, which is paramount for industrial processes.

Versatility: With a wide range of products tailored to different temperature ranges and environments, Optris can meet diverse industrial requirements.

Ease of Use: Optris devices are designed with the user in mind, featuring intuitive interfaces and easy setup procedures.

Worldwide Support: Optris provides extensive customer support, including training, maintenance services, and technical assistance, ensuring that users maximize the benefits of their temperature measurement tools.

In conclusion, whether you are involved in high-temperature industrial processes or require detailed material analysis, Optris’ IR thermometers and pyrometers offer the technological edge necessary for success. Their precision engineering, combined with outstanding customer service, makes Optris a smart choice for professionals who cannot compromise on quality and reliability in temperature measurement.