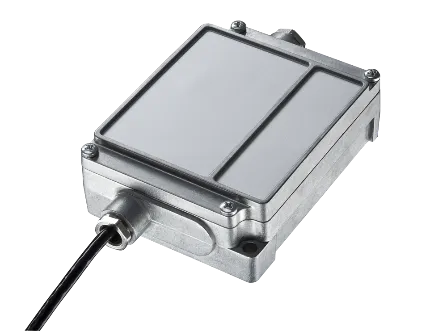

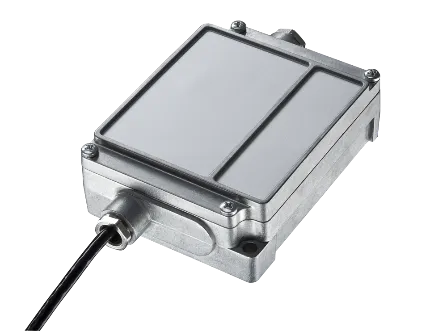

Industrial Process Interface for Ethernet-based Infrared Cameras

.

- Enhances analog and digital integration options

- Supports three analog and three alarm outputs

- Supports two analog inputs, one digital input

- 500 VAC isolation for safety

- Cascade up to three industrial process interfaces

- Integrated fail-safe mechanisms

From 225,00€

Product Description

The stackable process interface for the Ethernet-based Xi series enhances functionality in industrial settings. It supports up to three analog and alarm outputs, two analog inputs, and one digital input, allowing versatile control and monitoring. Cascading up to three interfaces expands outputs to nine. Integrated fail-safe mechanisms monitor conditions and trigger alarms as needed.

Specification

General Specification

- Environmental rating: IP65 (NEMA-4)

- Operating temperature: -30 °C … 85 °C

- Storage temperature: -30 °C … 85 °C

- Relative humidity: 10 – 95 %, non-condensing

- Protection class: IP65

- Vibration: IEC 60068-2-6 (sinusoidal form), IEC 60068-2-64 (broadband noise)

- Shock: IEC 60068-2-27 (25 G and 50 G)

- Weight: 610 g (with 5 m cable)

- Size: 122 x 70 x 27 mm

- Cable length: 5 m high-temperature cable (standard), optional 10 m and 20 m

Electrical Parameters

- Power supply: 5 … 24 VDC

- LED display: 2 green LEDs for power and fail-safe 3 red LEDs for alarm relay status

- Isolation: 500 V AC RMS between the infrared camera and process

- Outputs: 3x analog / alarm outputs, 3x alarm relays

- Inputs: 2x analog inputs,1x digital input

- Ranges:

- 0/4-20 mA (for AO 1 – 3)

- 0 – 30 V / 400 mA (for alarm relays DO 1 – 3)

- 0 – 10 V (for AI 1 – 2)

- 24 V (for DI)

Programmable features

Analog inputs:

- Emissivity setting

- Ambient temperature compensation

- Reference temperature

- Uncommitted value

- Flag control

- Triggered snapshots, triggered recording, triggered line scan camera triggered event grabber

- Reset peak-/valley-hold

Digital input:

- Flag control

- Triggered snapshots, triggered recording, triggered line scan camera, triggered event grabber

- Reset peak-/valley-hold

Analog outputs:

- Main measure area

- Measure area

- Internal temperature

- Flag status

- Alarm

- Frame sync.

- Fail-safe

- External communication

- Center pixel (direct output)

Downloads

FAQs

What is the difference between the standard PIF and the industrial process interface?

The industrial process interface offers enhanced features such as 500 VAC isolation, multiple analog and digital inputs/outputs, and fail-safe mechanisms for monitoring various conditions, while the standard process interface has basic functionality with fewer input/output options.

What input and output capabilities does the industrial process interface lack compared to the standard process interface?

The industrial process interface supports up to three analog/alarm outputs, two analog inputs, and one digital input, along with fail-safe relay outputs. The standard interface typically has fewer input/output options and lacks some of these advanced features.

How many outputs and inputs does the interface support?

It supports up to three analog and alarm outputs, two analog, and one digital input.

Can the interface be expanded?

Yes, up to three interfaces can be cascaded, expanding the number of available outputs to nine.

How does the cascading of interfaces work?

Each stackable PIF must have its own RS485 address set on the board, allowing up to three interfaces to be cascaded.

What fail-safe mechanisms are integrated into the interface?

The interface monitors conditions like cable interruptions and software shutdowns, triggering alarms when necessary.

Is this interface compatible with all Xi series cameras?

No, it is only designed for the Ethernet-based Xi series, not for the PI series or the Xi 400 or Xi 640.

Scope of Supply

- 1x Industrial Process Interface (PIF) with connection cable

Related Products

Talk to us about your IR Temperature Measurement Requirements

Our Infrared Temperature Measurement experts can help you find the right Optris product for your application.