CTlaser Fast LT

The IR thermometer Optris CTlaser fast LT is perfectly suited for monitoring quick working processes due to its short configuration time of only 9 ms.

- Temperature range: -50 °C to 975 °C

- Spectral range: 8 µm - 14 µm

- Response time: 9 ms

- High Optical Resolution

- Very Fast Measurements

- Laser Sighting

From 765,00€

Product Description

The Optris CTlaser fast LT series sets an industrial standard in non-contact temperature measurement with precision, speed, and a wide temperature range. Its two-piece design integrates an infrared sensor with a 50:1 optical resolution, ideal for monitoring fast-paced manufacturing processes. These pyrometers excel in fixed-installed or fixed-mounted applications, ensuring consistent and precise temperature measurements. With a temperature range from -50 °C to 975 °C, optimized for non-reflective surfaces, they adapt well to dynamic industrial environments. Offering rapid response times and different focal points for flexibility, they guarantee exceptional accuracy and repeatability in temperature measurements. The series’ double laser aiming marks enhance accuracy, facilitating precise alignment and minimizing deviations, particularly beneficial in industrial and research settings.

Specification

| MODEL | CTlaser Fast LT |

| DETECTOR | |

| Detector | Thermopile |

| Measurement Principle | Single Color |

| Spectral Range | 8 – 14 µm |

| Response Time | 9 ms |

| Exposure Time | 9 ms |

| Sampling Frequency | 110 Hz |

| Exchangable Sensing Head | No |

| OPTICAL | |

| Distance to Spot ratio (D:S) | 50:1 |

| Spot size (SF optics) | 24 mm at 1200 mm |

| Other optics (FF/CF optics / add. CF lens) | CF1: 1.4 mm at 70 mm CF2: 3 mm at 20 mm CF3: 4 mm at 200 mm CF4: 9 mm at 450 mm |

| Focus | fixed |

| SIGHTING | |

| Laser Sighting | Double point laser with 635 nm at max 1mW |

| Video Sighting | none |

| MEASUREMENT | |

| Object Measurement Range | –50 … 975 °C |

| Accuracy | ±1 °C or ±1 % **2) |

| Repeatability | ±0.5 °C or ±0.5 % **2) |

| Temperature Coefficient | ±0,05 K/ K or ±0,05 %/ K **3) |

| Thermal Sensitivity (NETD) | 100 mK |

| Warm-up time | 10 min |

| Emissivity /Transmissivity/ Reflectivity | 0.100 – 1.100 |

| Slope | N/A |

| INTERFACES | |

| Interface | USB / RS232 / RS485 / Profibus / Ethernet / Relay |

| Supported Protocols | USB 2.0, Optional: EtherNet/IP / Ethernet TCP / Modbus TCP / Modbus RTU / Profinet / Profibus |

| Compatible Software | Compact Connect, IRmobile |

| ANALOG INPUT/OUTPUT | |

| Direct output/input | 0-20 mA/4-20 mA/0-5 V/0-10 V/t/c (K/J) |

| Output impedances | max. 500 Ω (with 8-36 V DC) for mA output min. 100 kΩ load impedance for mV output thermocouple 20 Ω |

| Cable length | 3 m (standard), 8 m, 15 m |

| SIGNAL PROCESSING | |

| Configuration | Compact Connect or IRmobile |

| Operation | Autonomous Standalone |

| Capabilities | Average, Peak hold, Valley hold, Advanced peak hold with threshold and hysteresis, Triggered signal output, Triggered peak hold function (adjustable via software) |

| GENERAL | |

| Size | Sensing head: Ø50 x 100 mm, M48x1.5 Electronics: 122 mm x 70 mm x 27 mm |

| Housing Material | Stainless Steel |

| Weight | 600 g (sensing head) / 420 g (electronics) |

| Country of Origin | Germany |

| ENVIRONMENTAL & CERTIFICATIONS | |

| Operating Temperature Range | Sensing head: –20 °C … 85 °C **4) Electronics: –20 … 85 °C |

| Storage Temperature Range | –40 … 85 °C |

| Relative humidity | 10…95 %, non condensing |

| Protection Class | IP 65, NEMA 4 |

| EMC | 2014/30/EU |

| Shock | IEC 60068-2-27 (25 G and 50 G) |

| Vibration | IEC 60068-2-6 (sinus shaped) IEC 60068-2-64 (broadband noise) |

| Standards | CE, UKCA, RoHS |

| POWER | |

| Power Supply | 8 – 36 V DC / 5 V USB / max. 1.2 W |

| Power Consumption | <250mW (with laser) |

| Current Draw | max 160 mA |

| Part number | OPTCTLLTF |

| Additional Remarks | 1) 90% energy 2) at ambient temperature 23 ± 5°C, object temperature > 0°C ; 3) for ambient temperatures <18°C and >28°C; whichever is greater 4) 50 °C with laser ON |

Areas of Application

The two-part infrared thermometer optris CTlaser fast LT has been designed for universal temperature measuring applications up to 975 °C. Research and development facilities relying on valid measuring data, as well as machine and system producers, favor the use of this device. The high-performance laser of the pyrometer is perfectly suited for temperature measurement of non-metallic surfaces.Among others, this includes materials like plastics, varnishes, wood, or paper. The IR thermometer is employed for, e.g., temperature control during welding of plastic components as well as in testing stations in the automobile industry. The CTlaser fast LT recognizes temperature changes within only 9 ms. It has been designed for especially quick measurements and thus ensures a thorough temperature surveillance of fast processes.* plastic

Software

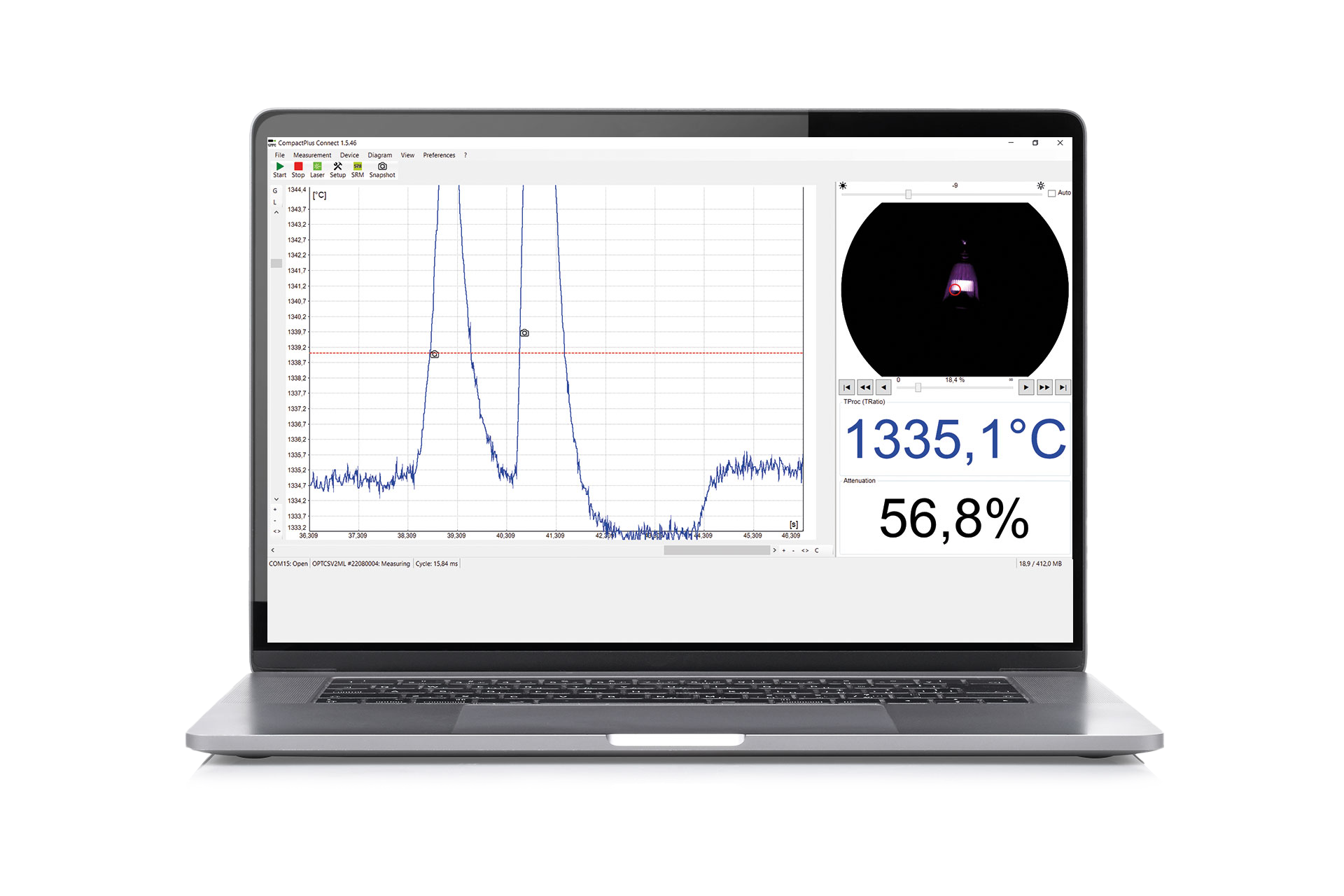

The Optris CompactConnect software improves the functionalities of Optris fixed infrared pyrometers, offering various monitoring, analysis, and control features beyond basic temperature measurement. It includes features like visualizing temperature trends with temperature-time diagrams and documentation. The software enables data logging, automatic process controls, parameterization of the pyrometer via configuration settings, and setting up programmable outputs and inputs. Additionally, it provides advanced signal-processing functionalities.

Compact Connect

The Optris CompactConnect software improves the functionalities of Optris fixed infrared pyrometers, offering various monitoring, analysis, and control features beyond basic temperature measurement. It includes features like visualizing temperature trends with temperature-time diagrams and documentation. The software enables data logging, automatic process controls, parameterization of the pyrometer via configuration settings, and setting up programmable outputs and inputs. Additionally, it provides advanced signal-processing functionalities.

Compact Connect

The Optris IR mobile allows users to set up and commission an Optris infrared pyrometer or infrared camera with an Android smartphone or tablet. This tool becomes handy for commissioning and aligning the infrared cameras field of view or adjusting the configuration. The app analyzes the connected infrared cameras live infrared image stream with auto hot and cold spot detection. For pyrometers, a temperature-time diagram or the video signal is displayed. This app works on most Android devices running 5.0+ with a USB port supporting USB-OTG (On The Go).

Google Play

The Optris IR mobile allows users to set up and commission an Optris infrared pyrometer or infrared camera with an Android smartphone or tablet. This tool becomes handy for commissioning and aligning the infrared cameras field of view or adjusting the configuration. The app analyzes the connected infrared cameras live infrared image stream with auto hot and cold spot detection. For pyrometers, a temperature-time diagram or the video signal is displayed. This app works on most Android devices running 5.0+ with a USB port supporting USB-OTG (On The Go).

Google Play

Downloads

FAQs

What distance-to-spot size ratio is correct for the application?

The measuring object’s size and the infrared thermometers optical resolution determine the maximum distance between the sensing head and the measuring object. To prevent measuring errors, the object should completely fill out the field of view of the optics. Consequently, the spot should always be at least the same size as the object or should be smaller than that.

Can I change the sensor cable?

The sensing head cable can also be exchanged if necessary. To avoid influences on the accuracy use an exchange cable with the same wire profiles and specification like the original one

Can I pare the sensor head with another electronics box?

Yes, after exchanging a head the calibration code of the new head must be entered into the electronics. The calibration code is fixed on a label on the head. Do not remove this label or note the code. The code is needed if the electronic must be exchanged.

How far can I position the CTlaser fast LT from the target?

The measuring object’s size and the infrared thermometers optical resolution determine the maximum distance between the sensing head and the measuring object. The object should fill out the optics’ field of view to prevent measuring deviations. Consequently, the spot should always be at least the same size as the object or smaller. The spot size refers to 90% of the radiation energy.

How can I improve the noise amplitude of the sensor?

In the CT models, the head cable must not be moved during the measurement. Use shielded cables only. The sensor shield has to be grounded. Avoid ground loops and related signal interferences in industrial environments. It might be necessary to interrupt the ground connections inside the electronics box. To do this, switch the jumper inside the electronics box to another position. Review the manual.

How do I aim with a CTlaser fast LT?

The infrared sensor has an integrated double laser aiming, which helps align the sensor. The measuring spot is located within the two laser points. At the focus point of the appropriate optics, both lasers cross and merge as one dot, marking the minimum spot. The two laser points are for orientation only.

Is the laser dangerous?

The pyrometers laser is a class 2 laser with less than 1mW in the wavelength range of 500 nm to 650nm, according to EN 60825 1:2014. Do not point the laser directly at the eyes of persons or animals! Do not stare into the laser beam. Avoid indirect exposure via reflective surfaces.

The laser switched off?

At ambient temperatures >50 °C the laser will be switched off automatically. The laser should only be used for sighting and positioning of the sensor. A permanent use of the laser can reduce the lifetime of the laser diodes and might heat up the sensor.

Can I trigger the laser externally?

Yes, but the supply line for the sighting laser must be led via a switch or pushbutton, which has to be installed max 2m away from installation site of the sensor for safety purposes. The laser can be activated/ deactivated via this, by the user on site to be installed switch, or via the software.

What is required to install the CTlaser infrared sensor in the CoolingJacket Advanced?

The connector version is needed to install the CTlaser sensor in the CoolingJacket Advanced.

Scope of Supply

- CTlaser fast LT with 3m cable

- 1x mounting nut

- 1x mounting bracket

- CTlaser Manual

Accessories

Talk to us about your IR Temperature Measurement Requirements

Our Infrared Temperature Measurement experts can help you find the right Optris product for your application.